Wholesale Engineer Grade Reflective Sheeting | EG Vinyl Manufacturer

Quick Details of EG Engineer Grade Reflective Sheeting

Product item: KW-XS6000

Size: 1.22m*45.7m (can be customizable)

Surface Film: PVC

Properties: Glass Beads, Enclosed lens

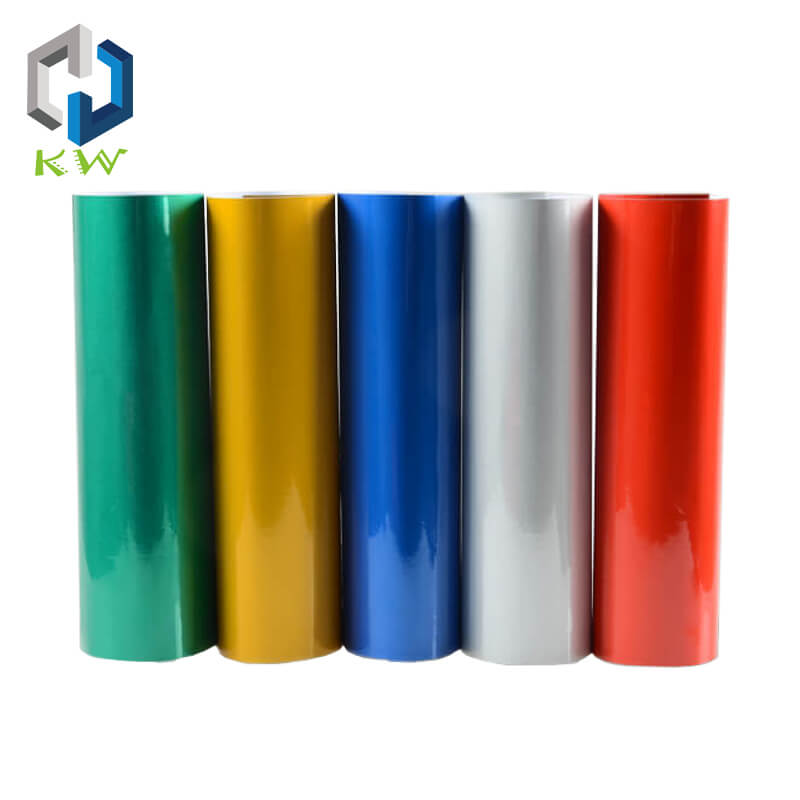

Color: White, Yellow, Red, Green, Blue, Orange, Black, and Customize

Adhesive: Press Sensitive Adhesive

Processing: Silk screen printing or Plotter cutting

Application: Intended for production of non-critical traffic signs and pressure-sensitive stickers

Product Description of Engineer Grade Reflective Sheeting EG Vinyl

Engineering Grade Reflective Sheeting, or EG reflective sheeting for short, is an Engineering grade of glass bead reflective sheeting that has extremely high levels of reflectivity. This product has a 1-3 year performance life and is available in a non-tearable PET substrate in a range of eight colors.

Engineer Grade Reflective Sheeting is self-adhesive with a pressure-sensitive adhesive and poly liner. The standard width available is 1.22 meters. Other widths are available upon request.

Retroreflectivity simply refers to the property of a traffic sign or device to reflect light back to the driver to increase nighttime visibility. Retroreflectivity degrades over time, necessitating the need for the systematic replacement of signs and work zone devices to maintain the retroreflectivity standards established and required by FHWA.

Engineer Grade Reflective Sheeting is a beaded technology material designed for use on non-critical traffic signs and is highly resistant against the extremes of hot, cold, dry, and humid weathering conditions. Meets ASTM D4956 Type I specifications.

Whether at work or play, KWVINYL KW-XS6000 Engineer Grade Reflective Sheeting helps your work to be seen at dawn, dusk, or night in all weather conditions. Traffic signs using EG vinyl and clear process colors are highly visible day or night and contribute greatly to driving safety. The panels are available in seven standard colors with a pre-applied pressure-sensitive (PS) adhesive.

Safety protective equipment within the reflective material can cause a strong reflective effect under certain light irradiation to provide the most effective and reliable security for the pedestrian in the dark or night operation personnel.

KW-XS6000 Engineer Grade Reflective Sheeting is a PVC surface engineer grade reflective sheeting film, it’s digital printable and screen printable, and also available for plotter cutting. KW-XS6000 Engineer Grade Reflective Sheeting has standard colors such as white, red, orange, yellow, green, blue, brown, black, etc.

Durable enclosed lens reflective sheeting with pressure-sensitive adhesive backing for application to standard traffic sign substrates by hand or in an Interstate squeeze roller applicator. Meets ASTM D 4956 Spec Type I, Class 1. 1-3 year durability.

Engineer grade reflective sheeting is flexible and cuttable, very easy to process, please test it before your application. It’s widely used in ordinary road signs, advertisement signs.

Handle with caution to avoid damage to its surface the engineer grade reflective sheeting is delivered inside a cardboard box free of dust, moisture, and the vinyl is held by two bases, which do not allow folding or abuse the roll by the edges when handling or stowing it the roll, in turn, is covered by a common plastic layer to increase their protection has the rules for traffic signs, required by the SCT is not recommended to apply on unpainted stainless steel always test on the specific substrate before application wet method of application is not recommended for this vinyl.

Feature Of Engineer Grade Reflective Vinyl

Engineer Grade Reflective Vinyl (EG) is the most basic type of retroreflective sheeting, also referred to as Type I. Typically specified for use on the non-critical street and road signs such as parking signs or way-finding signs and daytime work zones. It has less reflectivity than its counterparts.

Engineer grade reflective sheeting is also used often for reflective stickers and decals and generally lasts approximately 1-3 years. The sheeting may be hand-cut, band sawed, guillotined, cold or hot die-cut, and electronically cut. Application Temperature: 65F (18C) minimum (sheeting and substrate).

- Warranted outdoor durability of 1-3 years outlasts the competition and increases your customer’s satisfaction.

- Excellent reflectivity even when totally wet. Ideal for wet or dry weather conditions day and night.

- Obtain maximum impact for entrance signage as KW-3130 retains reflectivity when viewed at wide entrance angles.

- Apply to typical industrial substrates and flat surfaces only (not for vehicle application).

- Resists mild acids, alkalis, salt, and water.

- Available by-the-yard in popular widths.

- Enclosed lens retroreflective sheeting with glass bead retroreflector

- Designed for the production of non-critical traffic signs and pressure-sensitive stickers

- Pressure-sensitive adhesive backing with liner

- Meets ASTM D4956 Type I

Application Of EG Engineer Grade Reflective Sheeting

- For application to aluminum or plywood

- Intended for production of non-critical traffic signs and pressure-sensitive stickers

- Industrial signage

- Entrance signs

- Directional signs

- Warning / Traffic signs

Fabrication Of Engineer Grade Reflective Sheeting

Letters and characters should be a minimum height of 3 inches with a minimum stroke width of 3/8 inch.

Cutting Engineer Grade Reflective Sheeting

Engineer Grade Reflective Sheeting may be hand-cut, band sawed, guillotined, cold or hot die-cut, and electronically cut.

Electronic Cutting Machines:

Users are encouraged to evaluate cutting procedures for their own equipment and shop conditions. However, these general recommendations should be followed to

ensure easy handling.

- 1. There should be enough downforce on the knife blade to slightly score the liner. Too little downforce will not completely cut through the sheeting and adhesive. Too much downforce will cut through the liner, dull the blade and serrate the cut edge.

- 2. The knife blade should be sharp and clean. If there is adhesive on the blade, wipe it off with mineral spirits or isopropyl alcohol.

- 3. Sheeting temperature should be at least 65˚F (18˚C) or higher. If the sheeting temperature is less than 65˚F (18˚C), allow it to condition at 65˚F – 75˚F (18˚C – 24˚C) for at least 24 hours.

Weeding – Weed (remove) the excess sheeting as soon as possible after cutting. After more than 24 hours, the adhesive may flow into the cut areas and make weeding more difficult.

Shipment & Payment of Engineer Grade Reflective Sheeting

- Sample: Samples under 0.5KG are free of charges, but shipping fees required

- Bulk lead time: 5-15 days more or less, based on your quantities

- Supply Ability: 50000 Square Meter/Square Meters per Month

- Mode of transport: Sea Freight, Rail Freight, Air Freight, Express

- Terms of payment: TT / LC, E-checking & Credit Card /Western Union/ Cash

- Packing & Shipping: Standard export Paper package; By EMS, DHL, FedEx, TNT, UPS, or another express/ Our forwarding agent (by air or by sea)/ Your own forwarding agent/ Domestic forwarding agents to any city in China.

Frequently Asked Question

1. Q: Why choose us?

A: We have the latest and most advanced automatic production line of reflective materials, with an annual output of 8 million square meters of reflective sheeting.

2. Q: What is your payment method?

A: We prefer to T/T 50% deposit payment in advance, 50% balance paid off before shipment.

3. Q: Can you do customize the design and size?

A: Yes, our factory supports ODM &OEM, both design and size customization are available.

4. Q: Can we make a small order for engineer grade reflective sheeting?

A: Yes, we can accept small orders, but there won’t be a discount.

5. Q: What is the lead time?

A: As usual, we will complete the delivery within 15 days after your order.

6. Q: Can I get some engineer grade reflective sheeting samples for testing before placing the order?

A: Yes, we can provide you with some free samples for your reference if you would like to bear the express cost.

7. Q: Can you make other sizes and packages for Engineer Grade Reflective Sheeting?

A: Yes, we can make other sizes as your requirement, normally our quotation will contain the common package, if you need your own packages, you’d better advise your requirement ahead of time for an accurate quote.

8. Q: How about the quality?

A: Products of the indicators are in line with European standards EN471, TUV, SGS, and STATRA.3C, most of our products exported to the United States, South Korea, India, the European Union, and other more than and 50 countries and regions in the world. We have excellent product quality and customer service.

9. Q: Will you accept us to visit you?

A: Warmly welcome, we are in Quanzhou city, welcome to visit our factory.

Reflective Sheeting Suppliers and Manufacturers Factory Trading Company – KWVINYL

KWVINYL manufacturing is a professional printable reflective vinyl manufacturer in China since 2009. The factory is located in Quanzhou city and occupies more than 40 thousand square meters, with 1000 employees and modern production lines which are equipped with knitters, calender, coating and laminating lines, online checking systems, rewinding, and packaging, KWVINYL Manufacturing has become a full-scale innovation manufacturer in China.

We supply reflective sheeting products for vehicle safety, traffic signing, license plates construction safety, and commercial graphics applications, We offer both glass bead and micro prismatic films as well as s series of complimentary adhesive and fluorescent film products, Many of our products are customized for specific customer needs and applications, and we are always excited to take on new projects from a wide variety of industry segments.

Contact us to get a free sample of Engineer Grade Reflective Sheeting, and ask for a free quote of EG Vinyl, Today!

Commonly Asked Questions

You may be surprised to learn that paint is never used in the process of making traffic signs. Traffic signs are made by applying tremendous pressure to a .080 or .125 sheet of aluminum reflective vinyl film that creates a very durable bond. Once affixed, it is impossible to remove the material without damaging the sign. There are three types of reflective materials used to make traffic signs. They are engineer grade, high intensity, and diamond grade reflective sheeting. What is the difference between standard reflective or engineer grade (also known as Type I) and High Intensity (Type III) and diamond grade (Type XI) reflective sign materials?

Diamond grade reflective sheeting meets ASTM D4956 Class XI standards. This highly reflective sheeting uses 100% efficient, full-cube prism technology, reflecting almost twice the amount of light to the light source as high-intensity prismatic sheeting. Diamond grade reflective material is the highest grade of reflective material for traffic signs and is most commonly used on interstate highways and construction projects, as well as in areas where high visibility is critical. It includes fluorescent orange and fluorescent yellow-green colors and is most commonly used for school, sidewalk, and bicycle lane signs. What is Diamond Grade Reflective?

HIP Reflective Sheeting HIP reflective sheeting, known as High Intensity Prismatic Reflective Sheeting meets ASTM requirements D4956-09 Type III and IV and ASTM 4956-07 Type X. It is a non-metallized, microprismatic reflective sheeting used primarily for reflective traffic and roadway signs, barricades, or other road construction zone equipment, and traffic delineators such as cones or barrels. HIP sheeting is highly reflective and its durable topcoat protects signs and other traffic control devices from scratches and wear. It is not only highly reflective at night but also draws attention to itself during the day. HIP reflective sheeting is used for more permanent traffic signs, work zone equipment, etc., and is available in white, yellow, red, orange, blue, green, and brown. The manufacturing process for HIP reflective sheeting is also considered to be relatively “green” because it produces 97% fewer VOC emissions and uses 72% less energy to manufacture than engineer grade reflective sheeting. However, the reflectivity value alone is a better reason to use HIP. HIP reflective sign material has a longer life span than EG Engineer Grade Reflective Sheeting. This material is considered to be durable in the medium to long term, typically lasting about 10 years. What is HIP Reflective?

Engineer Grade Reflective Sheeting reflects at night when light hits the sign. The retro-reflective beaded material has a lifetime of 1-3 years. It generally is used for parking signs, other non-critical signs and also provides a less-expensive alternative. What is engineer grade reflective?