Retro Reflective Tape Wholesale Manufacturers Supplier – KWVINYL

KWVINYL Retro Reflective Tape Manufacturer is a leading reflective material supplier, retro-reflective tape sheeting factory, mainly providing & manufacturing top-quality reflective tape for kinds of reflective material distributors all over the world. Whether quality control or reflective sheeting tape production time, KWVINYL always does its best, serves every reflective self-adhesive vinyl customer well according to their requirements.

KWVINYL Retro Reflective Tape Manufacturer is a leading reflective material supplier, retro-reflective tape sheeting factory, mainly providing & manufacturing top-quality reflective tape for kinds of reflective material distributors all over the world. Whether quality control or reflective sheeting tape production time, KWVINYL always does its best, serves every reflective self-adhesive vinyl customer well according to their requirements.

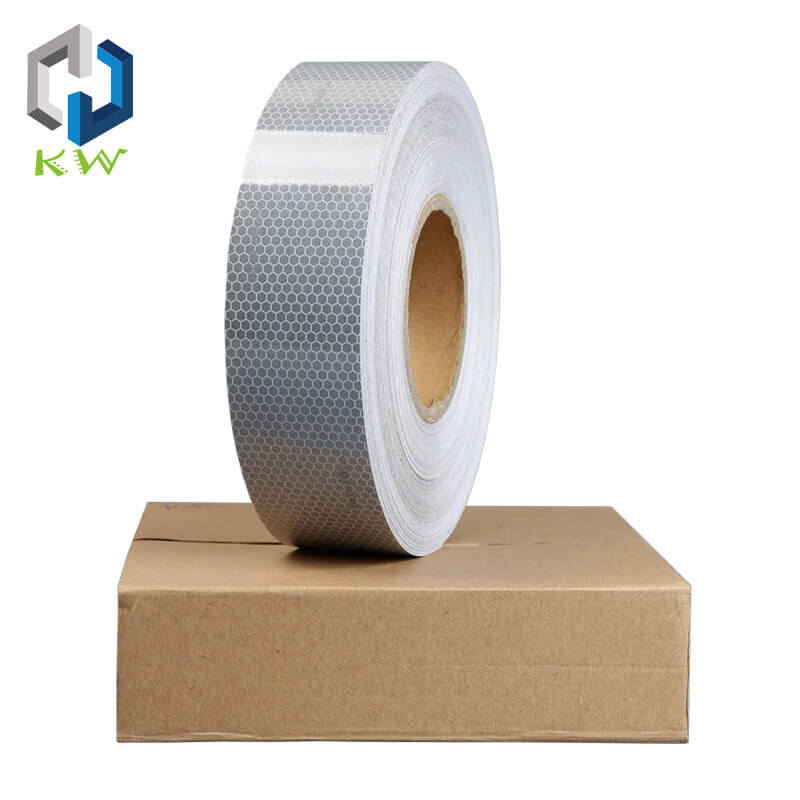

Reflective sheeting tape is one of the reflective products of KWVINYL, made by PVC/ PC/ Acrylic/ PET or mixed face film, our reflective material customers can choose the suitable reflective vinyl according to their product, reflective PVC films are good for digital print, reflective acrylic/PC film is suitable for screen print, PET reflective film can accept plotter cutting, and all of them can be used to do UV printing.

Of course, if you have strict requirements about reflection value, we also provide different reflective sheeting with kinds of reflective value.

If You Are Interested In Any Of Our Products Or Would Like To Discuss A Custom Order, Please Feel Free To Contact KWVINYL and Ask For A Quick Quote, Now!

Table Of Contents

- 1. Retro Reflective Tape Overview

- 2. Definition Of Retro Reflective Tape

- 3. How Does Retro Reflective Tape Work?

- 4. History Of Reflective Tape

- 5. How are Glass Beads and Microprismatic Reflective Tape Made?

- 6. Reflective Tape Classification

- 7. What is The Brightest Reflective Tape?

- 7.1 Flexible Engineer Grade Type 1 Reflective Tape

- 7.2 Flexible High Intensity Type 3 Reflective Tape

- 7.3 High Intensity Type 3 Reflective Tape

- 7.4 Non-Metallized Micro Prismatic Reflective Tape

- 7.5 Type 5 Metallized Micro Prismatic Reflective Tape

- 7.6 KW-3240 Metallized Prismatic Reflective Tape – (Compared to Type 5)

- 7.7 KWVINYL’s KW-3265 Conformal Metallized Prismatic Reflective Tape

- 7.8 SOLAS Metallic Micro Prismatic Tape

- 8. Reflectance Specifications for Different Types of Reflective Tape

- 9. How to Reduce Rear-End Collisions

- 10. Applications of Reflective Tape

- 10.1 Reflective Tape for Snow Poles and Snowy Winters

- 10.2 Reflective Tape for Automatic and Manual Gates and Fences

- 10.3 Sewn To Clothing

- 10.4 Vehicles and Trailers

- 10.5 Highlighting Objects On The Edge Of Driveways

- 10.6 Bikes and Motorcycles

- 10.7 Letterboxes

- 10.8 Reflective Tape Applied To Bike/Motorcycles Helmets

- 10.9 Boats and Ships

- 10.10 Life Jackets

- 10.11 Sewn To Children’s Bags

- 10.12 Bollards and Posts

- 10.13 Ledges and Steps

- 10.14 Low Hanging Objects

- 10.15 Witches Hats / Safety Cones

- 10.16 Warehouse Floors

- 11. How to Install Reflective Tape

- 12. Retro Reflective Tape Manufacturers Company Profile

Chapter 1. Retro Reflective Tape Overview

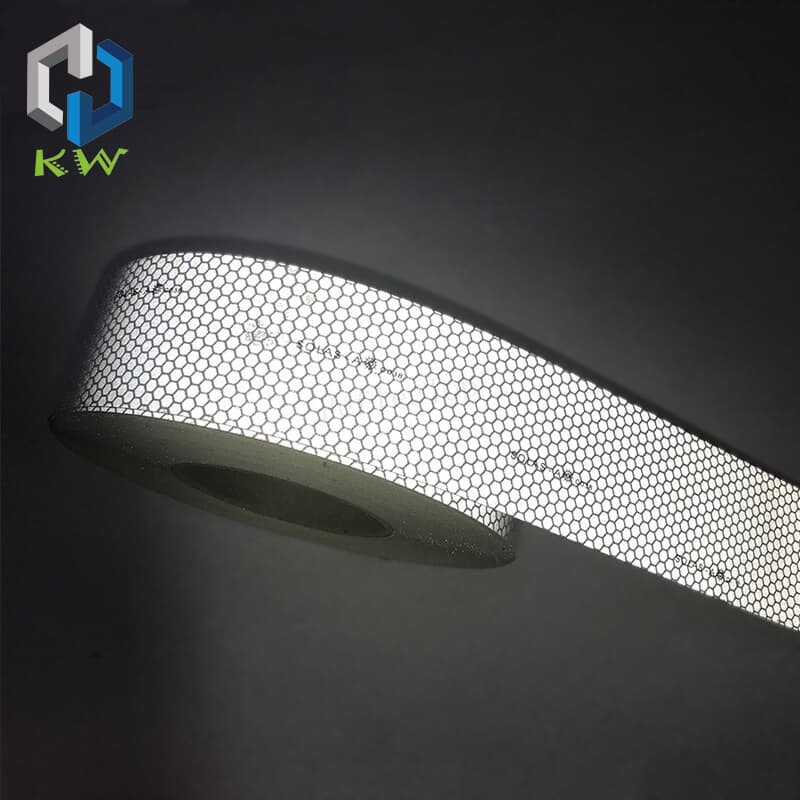

Reflective tape, also known as retro-reflective tape as well as conspicuity tape, is defined as a film that reflects light or radiation back to its source through the use of glass beads or artificial prisms. Glass Bead Reflective Tape uses glass beads that act as parabolas to reflect and direct light back to their source. The prismatic reflective tape uses an artificial prism or mirror to collect light and send it back to the light source. When a transparent color is applied to the surface of either tape, the reflected light is colored.

Reflective and retro-reflective surfaces are often confused with each other. Retro-reflective surfaces are always reflective, but reflective surfaces are not always retro-reflective. For example, a mirror is reflective, not retro-reflective.

(Note: Retro-reflective tape is often abbreviated as “reflective tape.”)

One of the most important features of retro reflective tape is its ability to collect light, change its color, and send it back to the light source. This is why red stop signs can be seen at night. Yellow yield signs are visible at night. And so on. Without this feature, night driving would be different than it is now.

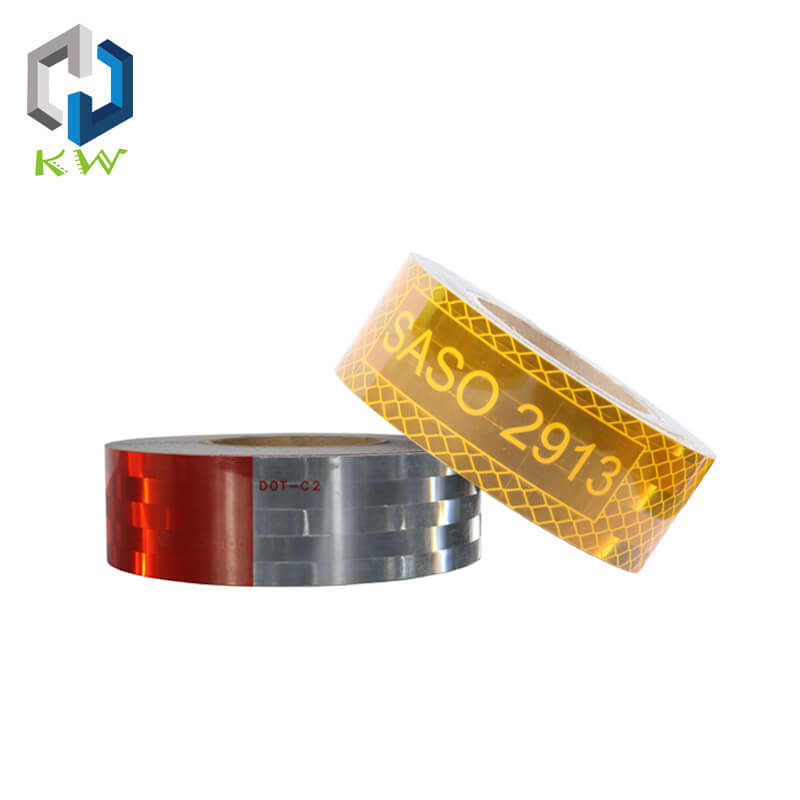

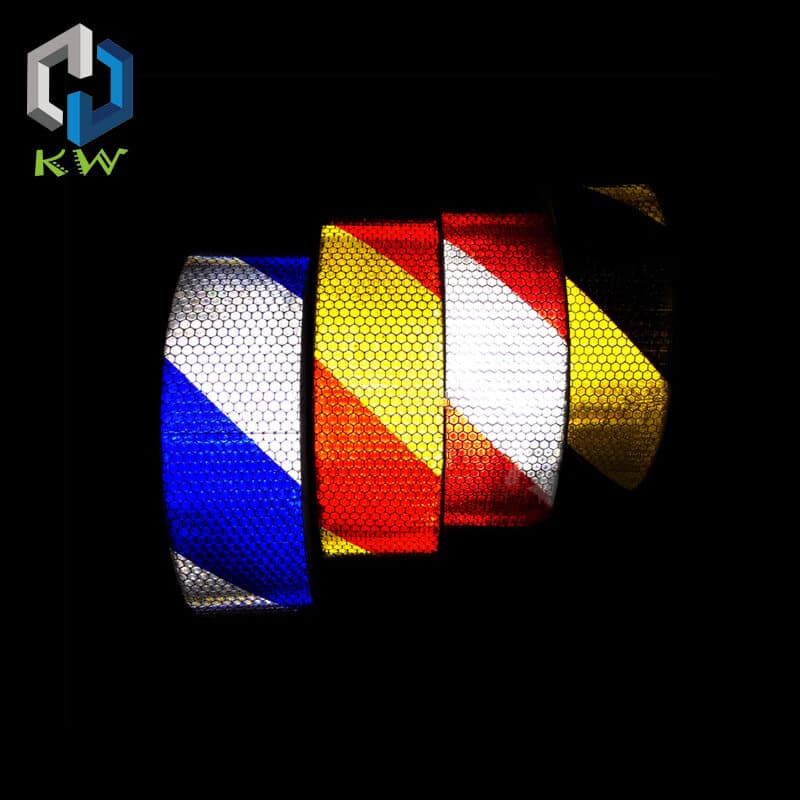

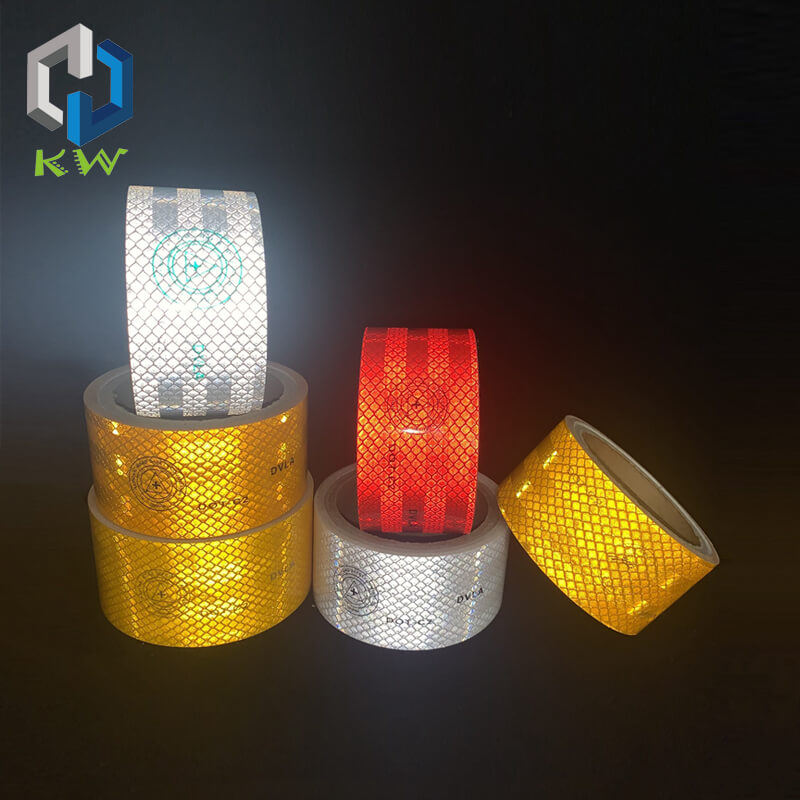

The types and colors of reflective strips are incredible. The variety of applications leads to the need for all the different intensities, types, and colors. For example, trucks need bright alternating red and white DOT tape that can be seen from thousands of feet away. Life jackets need a super bright white SOLAS tape that can be seen even from further away. Life-saving vests require sewn-in reflective tape, while trucks do not. Stop signs near communities can be made more reflective with glass beads, which are reasonably priced basic reflective tape. But signs on interstate highways require more expensive prismatic film. Distance dictates this necessity.

One of the most important features of retro-reflective tape is its ability to collect light, change its color, and send it back to the light source. That’s why stop signs are visible at night in red. The color of a yield sign visible at night is yellow. And so on. Without this feature, night driving would be different than it is now.

The types and colors of reflective tapes are mind-boggling. The variety of applications leads to the need for all the different intensities, types, and colors. For example, trucks need bright alternating red and white DOT tape (or NTC 5807 Standard Reflective Tape, ECE 104 Reflective Tape, Reflective Tape SASO 2913, etc.) that can be seen from thousands of feet away. Life jackets need a super bright white SOLAS tape that can be seen even from further away. Life-saving vests require sewn-in reflective tape, while trucks do not. Stop signs near communities can be made more reflective with glass beads, which are reasonably priced basic reflective tape. But signs on interstate highways require more expensive prismatic film. Distance dictates this necessity.

Chapter 2. Definition of Retro Reflective Tape

By definition, a retro reflective tape is a film that reflects light or radiation back to its source through the use of glass beads or man-made prisms. (Source — Cambridge English Dictionary)

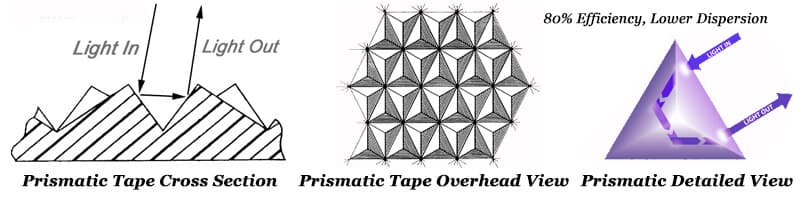

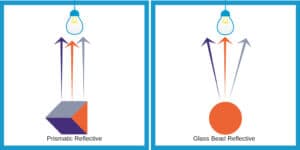

This may seem like a simple task, but it’s actually quite complicated. Just as you gaze at your portrait no matter where you are in the room, a reflective strip will only reflect light back to the light source wherever it is located. Think of it this way. If you are in the correct position in front of a parabolic shape (such as a satellite dish) and then throw a ball into the dish, it will always bounce back and hit you. If you throw the ball into the corner of the squash court, it will hit one wall, then another, then back to you. (In both examples, you must be in the correct position.) Glass bead retro-reflective tape (the original technology) is like a dish satellite dish, while prismatic retro-reflective tape (the newest technology) is like a squash court.

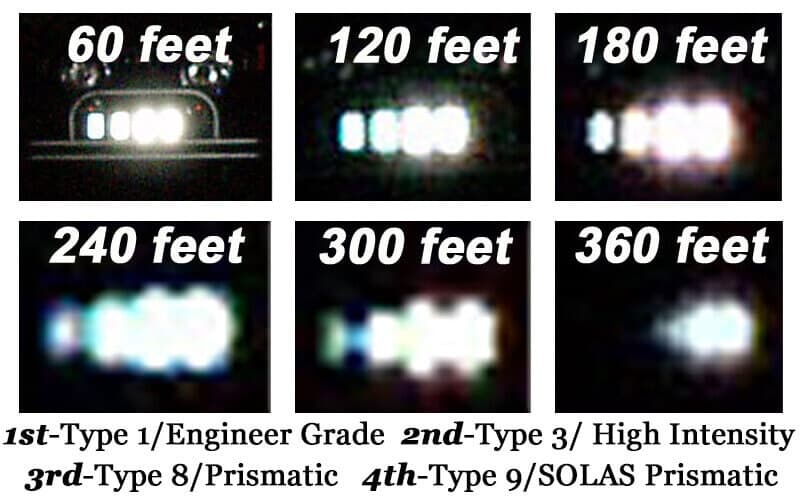

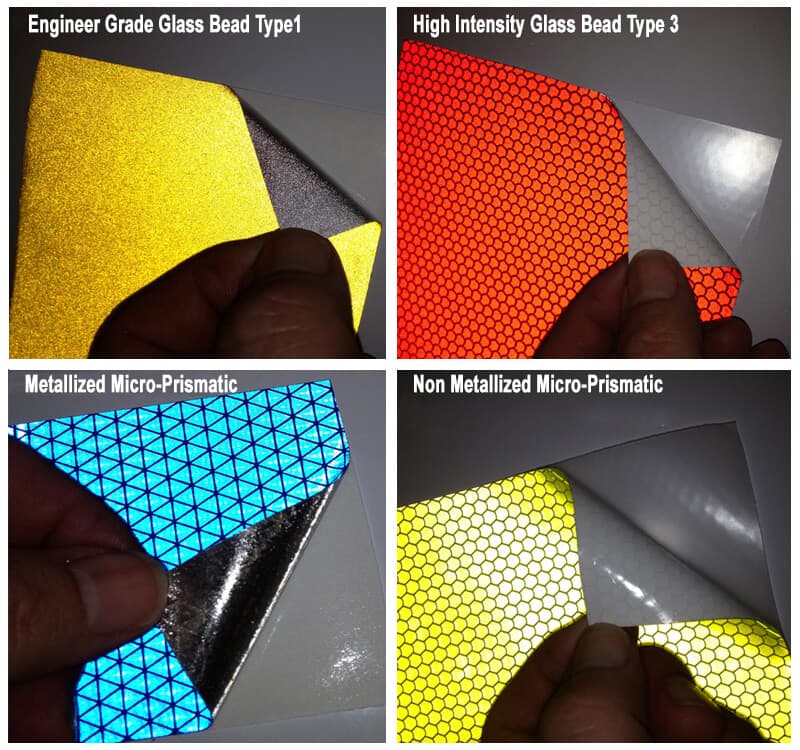

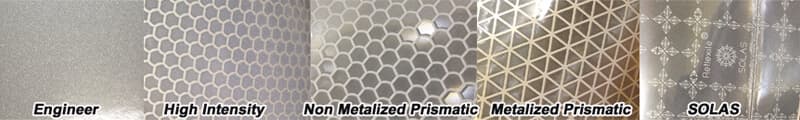

Figure 1 shows the four types of tape shot side-by-side at different distances with a flash. The two tapes on the left are glass bead tapes (engineer grade tape and high-intensity tape). The two tapes on the right are prismatic (High Intensity Prismatic Reflective Tape and SOLAS Tape) and, as you can see, the prismatic tapes can be seen from further away.

Pig.1 – 4 Different Type Of Reflective Tape

Often, reflective and retro-reflective tapes are confused with each other. All backward-reflecting surfaces are reflective, but not all reflective surfaces are backward-reflective. Consider a mirror. It’s reflective. However, if you shine the light at an angle, the light bounces and hits other areas. That’s because it’s reflective, not retro-reflective. If the mirror is reflecting backward, then the light will always come back to you.

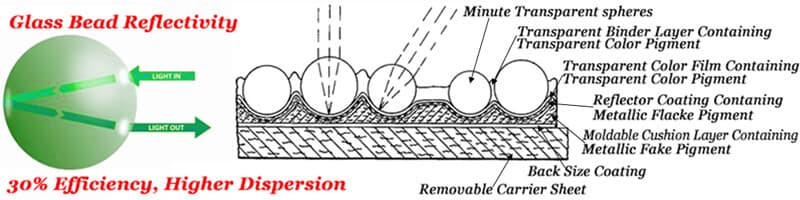

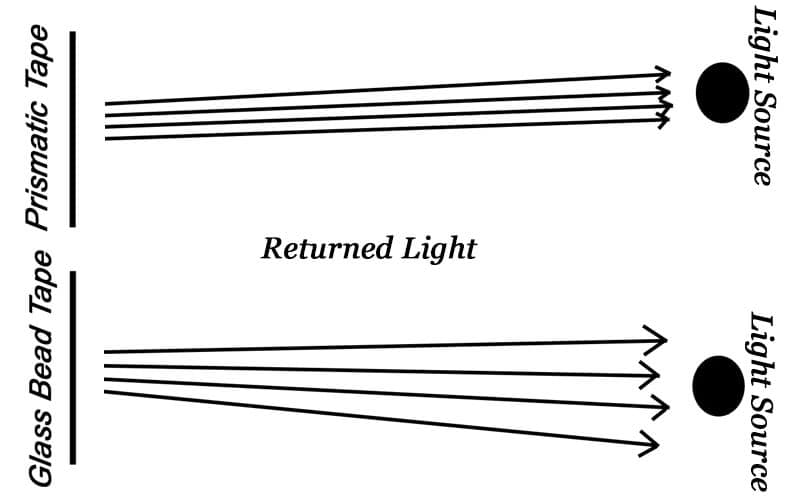

There are two types of retro-reflective tape, one is glass bead type reflective tape, which is the original technology. These tapes are retro-reflective at about 30% and tend to disperse the light back in a wider dispersion. This is actually a good thing for close-range applications, but not for long-range applications. The pattern is similar to that of a floodlight. It illuminates up close but does not illuminate as well at a distance.

The other type is prismatic reflective tape. Prismatic tape is much more retro-reflective (80%) and reflects light in a much tighter pattern. The reflected beams will be much like spotlights. The beams stay tighter and stay together for longer distances. (Example – lighthouse beams can reach the ship by using a lens to concentrate them into a tight beam.)

Finally, it is important to remember that the denser the beam, the more your eyes need to be aligned with the light source in order to see it as it reflects back. Car headlights and driver’s eyes are in this basic configuration, which is why drivers and passengers see road signs lit up while the next bystander doesn’t see any reflection at all.

Chapter 3. How Does Retro Reflective Tape Work?

You see the reflective tape every day and every night. But have you ever stopped to think about how it works?

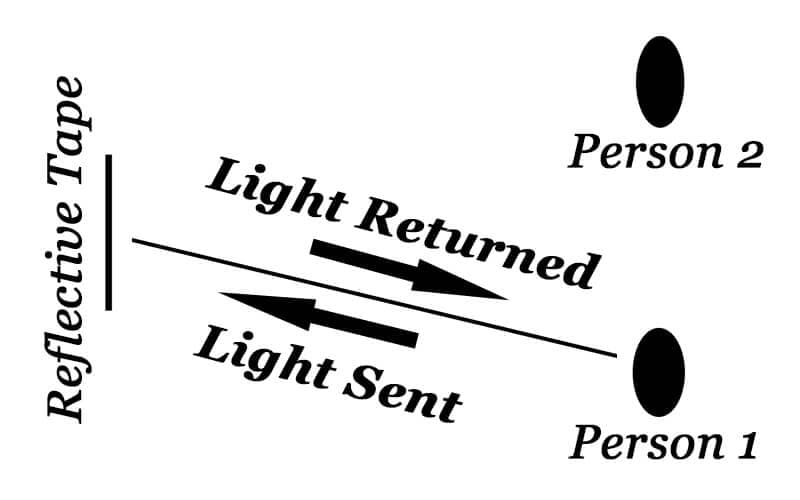

Reflective tape (also known as retro-reflective tape) works by reflecting only light back to the light source. In other words, the tape will only illuminate for people who have a light source or are aligned with a light source.

For example, suppose two people are walking along the same street, with people on both sides of the street. If person “A” has a flashlight and will illuminate some reflective tape on a trailer in the street, the tape will light up for him. However, a person on the other side of the street may not see the tape light up. If both illuminate the reflective tape, they will both see the tape. This happens because the tape contains glass beads or prisms that gather light, focus, and bounce back to the light source.

Fig.2

For example, suppose two people are walking along the same street, with people on both sides of the street. If person “A” has a flashlight and will illuminate some reflective tape on a trailer in the street, the tape will light up for him. However, a person on the other side of the street may not see the tape light up. If both illuminate the reflective tape, they will both see the tape. This happens because the tape contains glass beads or prisms that gather light, focus, and bounce back to the light source.

How does it work? Imagine that you are in a circular room and in the center of the room. If you throw a ball at the wall, it will always come back to you. Reflective tape works in a similar way. Figures 3, 4 show how a glass bead or prismatic works.

Fig.3 – Glass Bead Reflective Tape Working Principle

Fig.4 – Prismatic Reflective Tape Working Principle

As you can see in Figure 3, Figure 4, the tape refracts or bends the light in a certain way so that the light is always extinguished. This brings us to another amazing feature of reflective tape. In Fig. 2, one has a light and the other does not. If both have indicator lights, both lights will come on. Amazingly, the tape does not have to be horizontal to the viewer to reflect the light back. It can also reflect back multiple beams of light in multiple directions. It’s best to be flush with the light, but even at an acute angle, you’ll get a good return of light.

Another thing to remember about reflectivity is that your eyes must be aligned with the light in order to see the reflection of the tape. Next time you’re out behind a tractor-trailer at night, notice how you see the reflective tape come on as you walk backward. As you approach the brake lights, you will notice that the reflective tape no longer lights up. This is because the angle from the light to the tape to your eyes becomes too large. In other words, there is a big difference in the light in relation to your eyes. If you keep the light close to your head, the reflectivity doesn’t change when you get close to it.

Chapter 4. History of reflective tape – Who invented reflective tape?

Abstract – 3m invented the glass bead reflective tape in the 1930s and Reflexite invented micro-prismatic reflection in the 1960s.

Let’s start with the basics. Reflexivity was not invented. It has always existed in nature. The light bouncing off objects is why we can see those objects. Retroreflectivity has always existed in nature as well. The cat’s eye is an example of this phenomenon. (A parabolic lens creates a retroreflective surface) Hence the discovery of retroreflectivity, rather than being invented. What was invented was an artificial method of reproducing these features in a usable form.

There were two breakthroughs in retro-reflectivity technology. The first was a perfectly spherical glass bead and the second was a man-made prismatic. Both of these discoveries have played an important role in the history of reflective surfaces and tape. Let’s start with the glass beads.

Fig.5 – Glass Beads

4.1 Potters Beads

Potters is an American company that began producing tiny glass beads or balls in the early 1930s. It was important that the glass beads Potters created were very round or spherical. Only perfectly round and clear beads could send light back to their source. These very small and very round glass beads were used on cinema screens to make them brighter, and on-road stripes to make them more reflective. To this day, glass beads made by potters are still used on road stripes. Paint is applied and the beads are scattered over them while still wet. This is why the painted lines perform so well at night. It’s because round glass beads are sprinkled onto the paint surface and the glass beads absorb light from the headlights and bounce it back to you. Kind of like a parabolic mirror.

4.2 Engineer Grade Glass Bead Reflective Tape – ASTM D4956 Type 1

First, glass beads are applied to the surface of the sign and left bare. The reflectivity achieved is very low, even lower in the rain. Also, over time, dust would accumulate between the beads and further limit the visibility. This experiment was a start, but further improvements were needed. In 1937, 3m began to develop a film that utilized glass beads bound to a flexible surface. Their intention was to use this tape on road surfaces, but after some durability problems, they turned their focus to road signs.

To create the brighter tape, 3M created a silver substrate or film similar to the back of a mirror. They then applied glass beads to that surface so that about half of the beads were embedded in the silver backing while the other half was exposed. The silver backing turns the back of the beads into a mirror and provides the shape of the beads for returning light to the light source. A transparent layer is applied to protect the reflective beads. This results in a brighter product. The clear layer keeps the glass beads protected so that the tape is visible even on rainy days. (Note: Different colors can be produced by tinting the topcoat) In 1939, 3m introduced what was then and is now known as an “engineering grade” reflective sheet. It was tested first in Minneapolis and then in England. Later, improvements to the Engineer Grade reflective tape would be made by using advanced mirroring technology and higher index beads. Similarly, changes to the top layer allow some versions to stretch and laminate while others become more rigid. Compliant types are used for vehicles, traffic cones, and road barrels, while more rigid types are used for signage. Engineer grade is also known as a closed bead. This simply means that the beads are dipped into the topcoat, thus sealing and protecting each bead. There are pros and cons to this type of construction. On the plus side, you can cut the tape and make letters or shapes and the integrity of the glass beads is not compromised. For this reason, engineer’s tape is so popular in the graphics industry because it cuts into the letters, shapes, and designs in the material. On the negative side, this type of construction reduces the overall reflectivity of the bead. Engineer grade or Type 1 film has a reflectivity of about 75 candelas for white and less for colored film. Same as for your car tags. For applications in the 100-150 foot range, this is adequate.

4.3 High Intensity Glass Bead Reflective Tape – ASTM D4956 Type 3

In 1971, 3m introduced their “high intensity” reflective sheeting. This tape or sheeting differs from the engineer-grade in that the beads are enclosed in cells, but not completely encapsulated. They are located in a honeycomb hexagonal compartment and are sealed by a clear or colored outer coating. In addition, the actual beads themselves are not metalized layers. Being metalized on its own without being encapsulated makes the beads more reflective. In fact, high-strength sheeting is three times more reflective than engineer grade sheeting. A high-strength sheet is ideal for sign backgrounds. Cutting tape is not usually used for letters or shapes because it opens up the cells and allows water to enter. (Note – only the cut cells are affected. All other cells remain sealed. Also. the cells are very small.) High strength or type 3 flakes represent the brightest tape that can be made using glass bead technology. Approximately 250-candela white. High-strength sheeting was and is widely used in sign making. Since the signs are static, the material performs well. The extra reflectivity allows vehicles to see further.

4.4 Competition to Enter the Glass Bead Reflective Tape Market

In the 1970s, several companies also entered the glass bead reflective tape market. Avery Products introduced a line of engineer’s grade reflective tape in the U.S. Avery Products was the first manufacturer to introduce a line of glass bead reflective tape in the U.S. Avery Products was the first manufacturer to introduce a line of engineer’s grade reflective tape in the U.S. Avery merged with Dennison and became Avery-Dennison in 1990. The Japanese company Seibu International launched a similar line overseas. In 1991, Seibu was acquired by Nippon Carbide (also a Japanese company) and the product was renamed Nikkalite.

4.5 Prismatic Reflective Tape – ASTM D4956 Type 4 and Above

In 1963, the American Rokwand brothers of Rokwand Products Inc. began developing micro-prismatic reflective sheeting. This was done in collaboration with Luce Reflexite and later with Fresnel Optics. These companies were later merged together. The product was patented in 1970 and a company called Reflexite was created to manufacture and market the new product. Reflexite began selling micro-prismatic sheets in 1973. Just as 3M is known for the invention of reflective glass bead tape, Reflexite is known for the invention of prismatic reflector tape. (Reflexite has since been purchased by Orafol)

Prismatic retro-reflective sheeting reflects light back to the light source, just like a glass bead reflective tape. The only difference is that prismatic retroreflective sheeting does this more effectively. In place of light entering the glass bead, it enters the prism. The straight edge of a micro-prism allows more light to enter and exit the prism. Prismatic tape is about 80% efficient, compared to about 30% for glass bead tape. Also, prisms are man-made and placed side by side in tight arrays, whereas glass beads leave some dead space between them. Like the glass bead tape, the micro-prism reflects on the backside. The front of the prism allows light to enter, while the back of the prism reflects it and sends it back. Like glass bead tape, there are two types of micro-prism or cubed cornered tape, metallized micro-prismatic and encapsulated lens.

The metallized film is popular in the graphics industry because it is a thin layer and does not delaminate. It has the same positive characteristics as engineer grade products but is 10 times brighter.

Encapsulated or non metalized prismatic mirrors are thicker and easier to delaminate. However, the lack of silver mirror coating results in more vibrant colors. Therefore, for sign films, a non metalized film is preferred.

In the Stimsonite of the 1980s, a major manufacturer of road reflectors introduced their own prismatic thin film. Subsequently, they were acquired by Avery-Dennison in 1999 and were able to add Stimsonite micro-prismatic foils to their glass bead line.

Nippon Carbide, who acquired Seibu, developed their own line of micro-prismatic films and was then able to offer a full range of reflective products from engineered glass beads to prismatic sheets.

In 1989 3M introduced a prismatic product called Diamond Grade Sheet, thus completing their line of reflectors.

In 2012, Reflexite Americas merged with Orafol, a German company with an impressive global presence. Prior to the merger, Orafol had a large portfolio of reflective films. (Primarily glass bead technology) The line was more than doubled by the addition of Reflexite prismatic reflective products.

The reflective tape business now has four main competitors. These are 3m, Orafol / Reflexite, Avery Dennison, and Nikkalite. All four companies have a line of glass bead and prismatic reflective tape. 3m’s glass bead reflective tape is actually the least competitive product in the glass bead market today. Their strategy has been to focus on prismatic tape and gradually discontinue the glass bead line. Whether this is a good move on their part remains to be seen.

Chapter 5. How are Glass Beads and Microprismatic Reflective Tape Made?

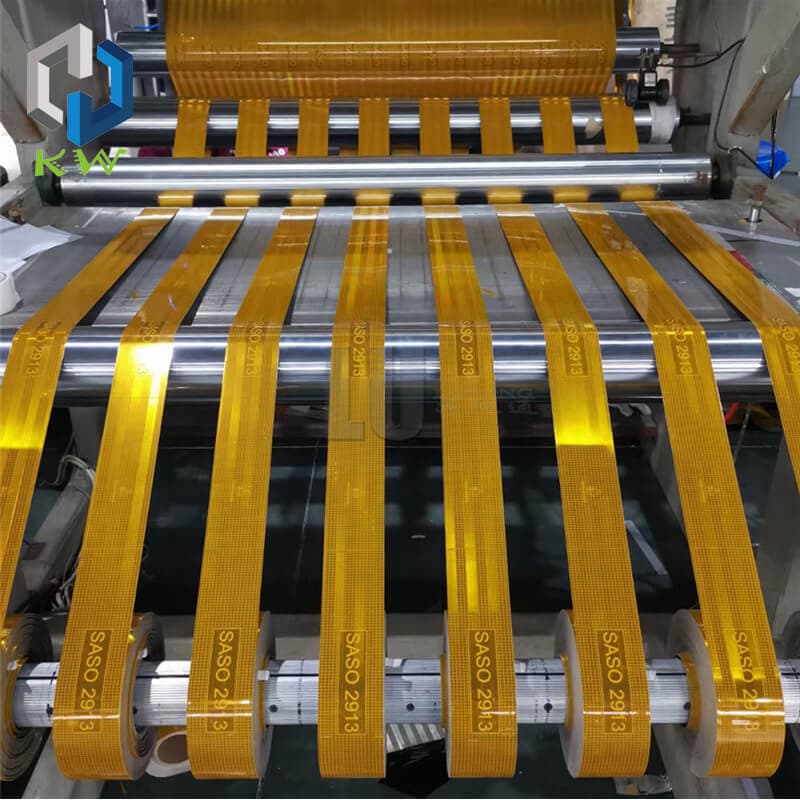

Reflective tape is made using a machine that bonds multiple layers of material together to form a thin film. There are two main types of reflective tape, glass beads, and miniature prisms. They reflect in two different ways but are made in a similar way, with glass bead tape being less complicated for both.

5.1 Engineer Grade Glass Bead Reflective Tape

The engineer grade reflective sheeting starts with a top metallized carrier film. Glass beads are applied to the layer so that approximately 50% of the glass beads are embedded in the metallized layer. This gives the glass beads their reflective properties. The top is then coated with a layer of acrylic or polyester. This layer can be transparent for the white reflective tape that is made, or it can be tinted to create different colors of reflective tape. A layer of adhesive is then applied to the bottom of the tape and an anti-adhesive liner is attached to that layer. Roll it up, cut it to a certain width, and sell it. Note – Acrylic laminated films do not stretch, while polyester laminated films do. Due to the heat used in the manufacturing process, the engineer’s grade film will end up as a single layer, so it will not be layered.

5.2 High Intensity Glass Beads Reflective Tape

High intensity Type 3 retro reflective tape can also be made in layers. The first layer (if there is a grid built into it). This is usually a honeycomb pattern. This pattern will hold the glass beads so that they are located in a separate unit. The glass beads are bonded to the bottom of the unit and then an acrylic or polyester layer is applied to the top of the unit to provide a small air space above the beads. (High refractive index beads) This layer may be clear or colored. A layer of adhesive and a barrier liner is then applied to the bottom of the tape. Note – The acrylic layer film will not stretch, while the polyester layer film will stretch. Although the high strength layers are bonded together, they may delaminate.

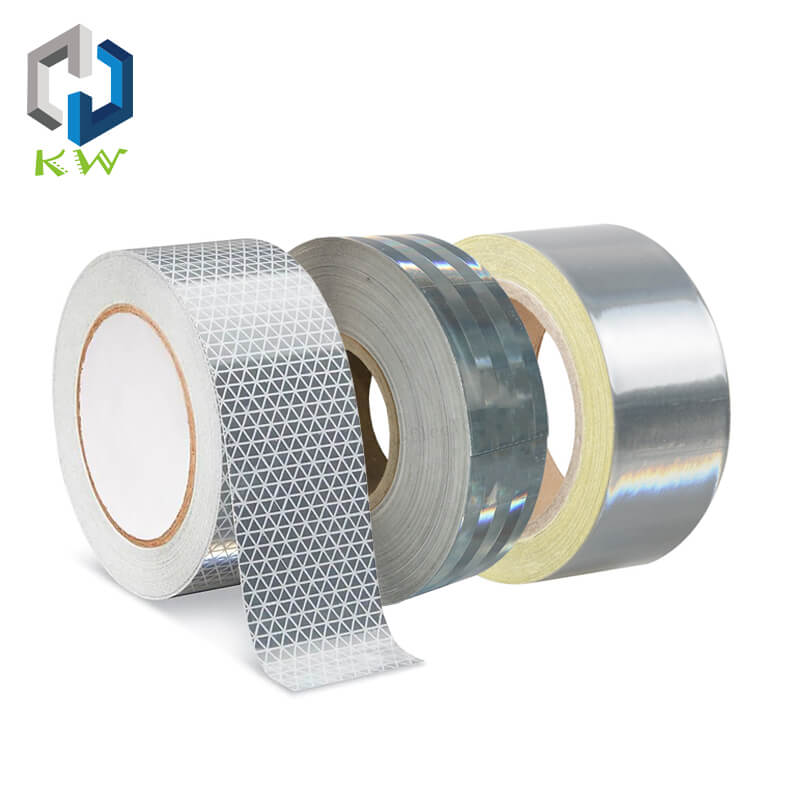

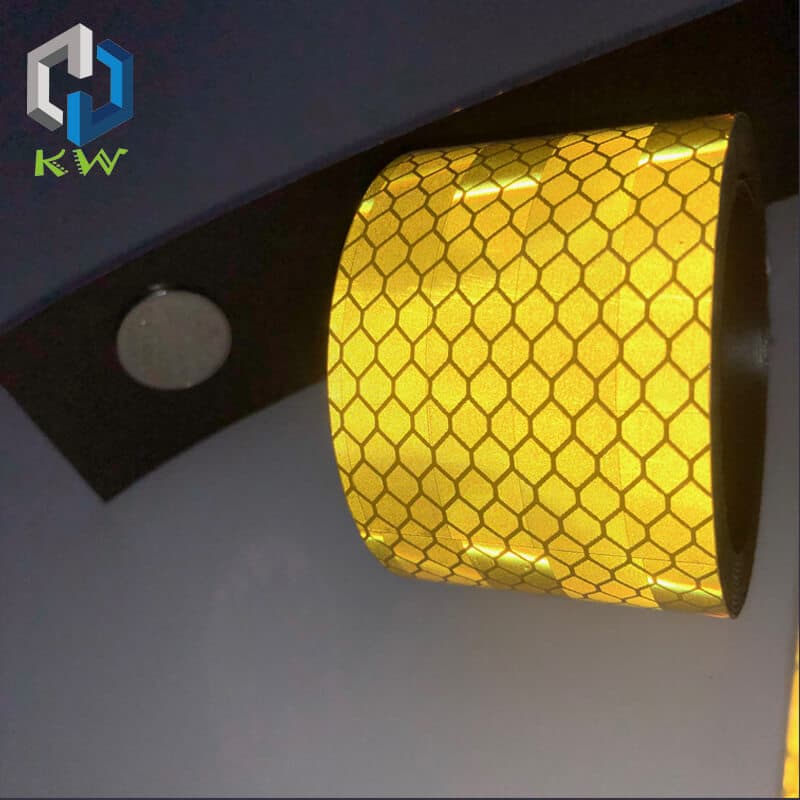

5.3 Metallized Micro Prismatic Reflective Tape

Metallized microprismatic reflective tape is made by first making a prismatic array of transparent or colored acrylic or polyester (vinyl). This is the top layer. This layer provides reflectivity and returns the light to the light source. The colored layer will return the light to the light source in a different color. This layer is metallized to enhance its reflectivity. An adhesive layer is then applied to the back and an anti-stick liner is applied. Due to the heat used in the process, the metallized prismatic layer will not delaminate. This is particularly beneficial in applications such as vehicle graphics or any other application where tape may require rigorous handling. Reflexite invented prismatic reflective tape and its strips will not delaminate.

5.4 Non-Metallized Micro-Prismatic Reflective Tapes

Very similar to metallized sheeting, the first step in making a non-metallized reflective sheeting is to make a prismatic array of acrylic or other transparent resins. This will be the top layer of the Film. It can be either transparent or colored. To produce a whiter or more vibrant colored film, the prismatic layer adheres to a grid that forms some sort of honeycomb pattern. This creates an air layer underneath the prism. The surface beneath the air layer is white. The prism layer and the raster layer are bonded together but can be separated, meaning that the non metalized film may be layered. By eliminating the prismatic metallization, the tape is more vivid because the color does not have to compete with the silver metalized layer. The non metalized film is more vivid, but not necessarily more reflective.

Figure 6 shows the four types of reflective sheeting. All are made in a similar fashion. Glass bead engineer grade films are the easiest to make and therefore the cheapest. High strength is a close second as the cheapest. Metalized micro-prismatic films are the most expensive to manufacture, yet the brightest and toughest of all reflective bands. They are well suited to dynamic or harsh environments. Non-metallized films are cheaper than metallized films. The advantage of non-metallized films is that they are brighter during the day and are widely used for signage and other static applications.

Fig.6 Four Types Of Reflective Sheeting

Chapter 6. Reflective Tape Classification

According to the structure, there are two types of reflective tape, glass beads, and micro-prismatic reflective tape, the glass beads reflective tape can be divided into high intensity reflective tape, engineer grade reflective tape.

Microprism reflective tape is divided into metallic and non-metallic reflective tape, non-metallic includes SOLAS Marine Grade Reflective Tape, DG Reflective Tape, HIP Reflective Tape, EGP Reflective Tape.

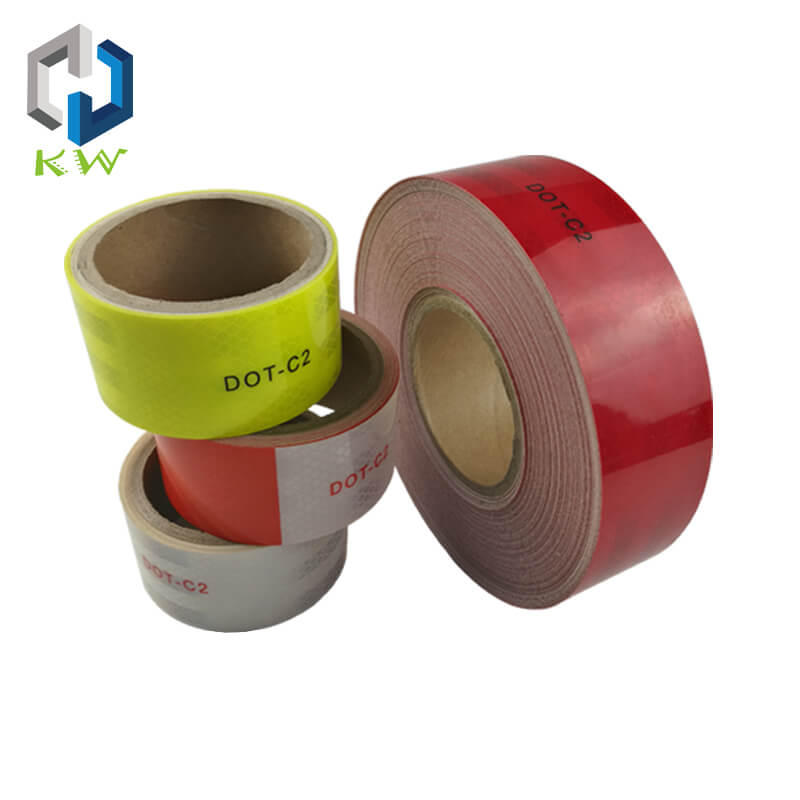

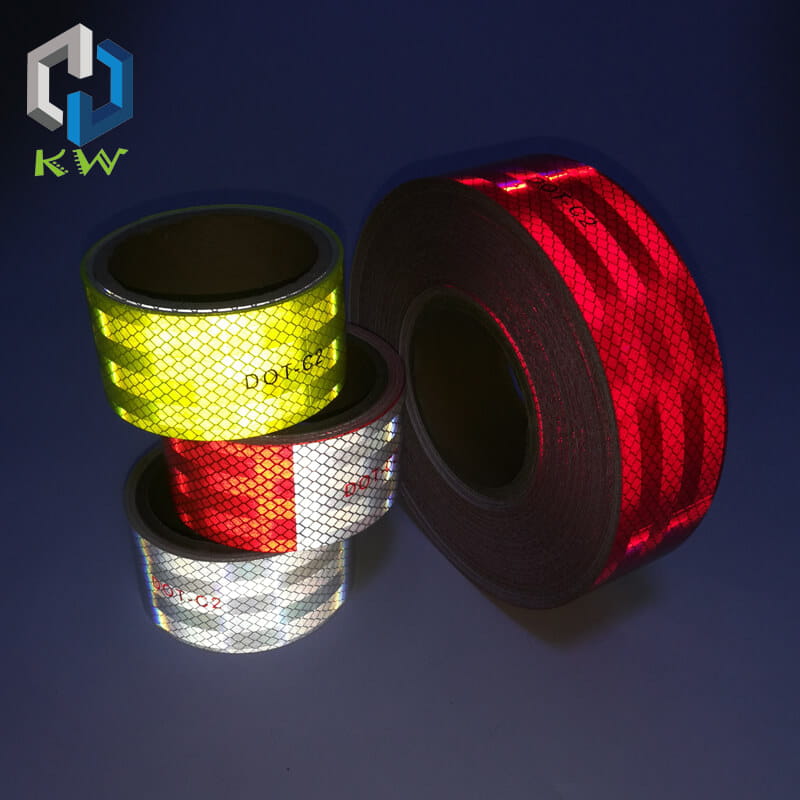

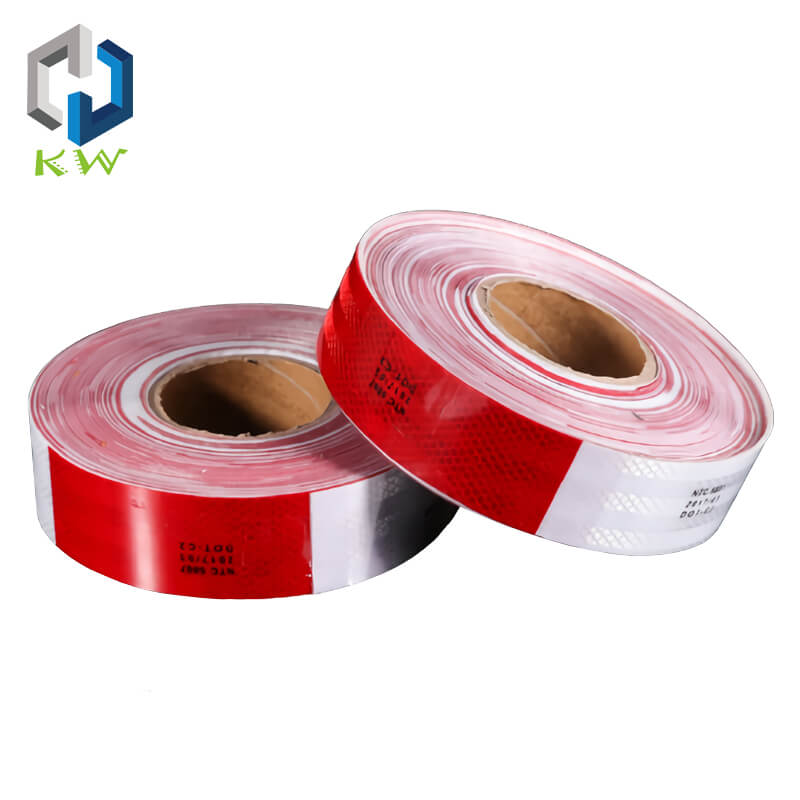

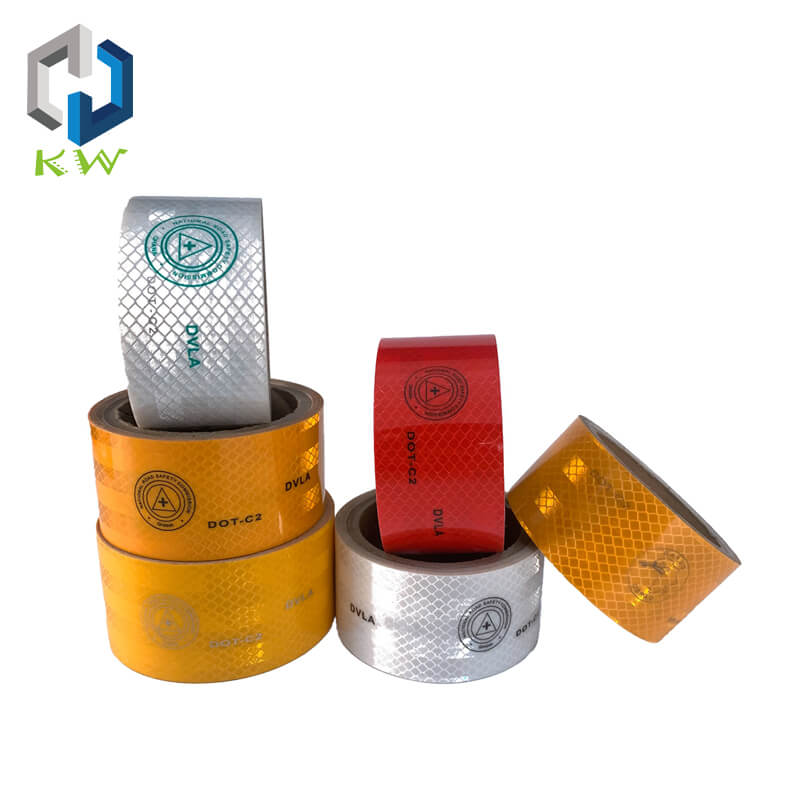

According to the standard of each country, reflective tape is classified as DOT C2 Reflective Tape (USA), ECE 104 Reflective Tape (Europe), Reflective Tape SASO 2913 (Saudi Arabia), NTC 5807 Reflective Tape (Colombia), Australia: Class 1W Reflective Tape, Class 1 Reflective Tape, Class 2 Reflective Tape, and more.

6.1 What is the Difference Between Glass Beads and Prismatic Reflective Tape?

There are two types of reflective tape, glass bead and prismatic. Glass bead tape was the first reflective tape, and then in the 1960s, Reflexite invented prismatic tape. Interestingly, the prismatic tape did not replace glass bead tape. Not even after 50 years. This is because both have properties that make them desirable in some situations.

Performance Differences – Glass Beads VS. Prismatic Reflective Tape

The reflective tape reflects in one of two ways. Through the use of microscopic glass beads or through a man-made prismatic. Glass bead technology is the oldest technology, while prismatic tape is the most recent.

Note – Prismatic reflective tapes were invented by Reflexite Americas in the 1960s.

Glass bead tape reflects light backless efficiently than a prism. However, glass bead tape is much cheaper. They are good, and sometimes preferable, for applications within 300 feet of the prism.

Prismatic reflective tapes have a tighter, more efficient light return. The brighter, tighter beam extends further, allowing prismatic tapes to work beyond the thousand-foot mark. For marine, highway, or traffic applications where long-distance visibility is important, prismatic is the way to go.

Fig. 7 shows the dispersion characteristics of each type of tape. The glass bead reflective tape reflects light back, just like a floodlight. Up close this is great. Prismatic tape glows like a spotlight.

Fig.7 Schematically of Glass Beads and Prismatic Reflective Tape Reflect Light

It’s better when the viewer is far away.

What’s the difference in brightness? Let’s compare white/silver. White glass bead tape reflects about 75 candelas for standard engineer grade type 1 tape (like your car tags) and 250 candelas for high strength type 3 tape. Prismatic tapes start at about 460 candelas, while SOLAS tapes go up to 1000 candela. As you can see, these two types are very different. Each has its own function and will never go out of style.

6.2 Glass Bead Reflective Tape

Glass bead ribbons use tiny glass beads to bend and reflect light back to a light source. Because of the defects and curved surface of the glass beads, belts made of beads are less reflective than tapes made of prisms. The efficiency of a glass bead tape is about 30%. This is a disadvantage. However, glass bead tape offers three advantages over most prismatic tape. First, glass-beaded reflective tape is much cheaper. This is because they are much easier to manufacture. Second, most glass bead tapes are CAD cuttable, which means you can cut out letters, numbers, and patterns from the tape and create reflective logos or graphics. Third, glass bead tape reflects light at a wider angle. In other words, glass bead tape is kind of like a floodlight, while the prismatic tape is more like a spotlight.

You’ll notice from Figure 7 that the glass bead tape disperses the light more than the prism tape. That is why it is not as bright at longer distances. However, at closer distances, the wider dispersion angle may be an advantage. For example, suppose a firefighter wears a high-intensity glass bead tape on his apparatus. When someone shines a light at him, the tape will light up for the person with the light, and it will also light up for you if you are very close. Also, when the light beam approaches the firefighter, his tape lights up quickly. Again, this is due to the scattering of the light. Many people prefer high-intensity glass bead tape for close-range applications. For long-distance applications, prismatic is always better.

There are two basic types of glass bead reflective tape. The first is standard engineer grade or type 1 tape. The white engineer grade tape reflects about 75 candle marks. This is the most popular type of tape and can be found on car tags, stop signs, speed limit signs, emergency vehicle delineations, and graphics. The second type of tape is high strength or type 3 tape. This tape has a high refractive index bead and encapsulates it into a honeycomb shape. White high-strength tape reflects about 250 candelas of light. You will find this type of tape on traffic cones and road barrels.

6.2.1 Enclosed Lens versus Encapsulated Lens Retro Reflective Tape Definition (enclosed=engineer grade / encapsulated=high intensity)

There are several types of reflectors, colors, brightness, etc. Some of the terminology used to describe the different types of reflectors can be confusing. This article will define the terms “enclosed lens” and “encapsulated lens reflective sheeting”. These terms relate to the construction of the reflector film. These two methods of construction also define the appearance of the tape. In other words, you can look at a sample of reflective tape and determine the type of construction used.

6.2.1.1 Enclosed Lens Retro Reflective Tape

This method of construction applies only to glass bead-type reflective sheeting. Enclosed lenses are also referred to as Engineer Grade (Type 1) or Super Engineer Grade (Type 2) Reflective Sheeting. The glass beads provide reflectivity by reflecting light back to the light source. Each glass bead acts as a lens. In a closed lens film, the glass beads are completely surrounded by the flexible polymer that makes up the film. Nothing other than light can enter the bead. The polymer that surrounds the bead is usually colored, which is what produces different colors. The top of the diagram below shows how it works. With this type of film, you can cut it into any desired shape without compromising the integrity of the bead. This is why this type of film is often used for graphic applications (such as letters and numbers on vehicles). A closed lens film usually has no visible pattern. Just a smooth color, such as white, red, green, blue, black, yellow, brown, gold, or orange.

6.2.1.2 Encapsulated Lens Retro Reflective Sheeting

Encapsulated lens reflective sheeting also refers to glass bead-type films. In particular, type 3 high-intensity films. In this type of construction, the glass beads are encapsulated in a cell. As long as the cell is intact, water and elements cannot reach the actual beads. However, cutting the film without using a clear coat to seal the cell will expose the cells at the edges and may result in water immersion. (Only the cells at the edges will be affected.) In other words, the bead is protected only within the cell. Because the beads are not completely surrounded by the polymer, they reflect much brighter. The tops of the cells they are in are transparent or colored to create a colored film. The bottom of the diagram above shows this type of construction. If you look at the encapsulated film, you will be able to see the honeycomb or diamond-shaped cells. If you look very close, you will see small beads. (If you see prisms within the cell, you are looking at a non-metallized prismatic film)

6.3 Prismatic Reflective Tape

The Prismatic is more efficient and returns about 80% of the light sent to it. As a result, it is brighter than glass bead tape. A prismatic tape reflects light through a man-made prismatic. Since the reflective sheeting is flat rather than curved, it is more efficient. The light sent from the tape is more concentrated, so it can be seen over greater distances. For long-range applications such as DOT control trucks or Coast Guard search and rescue, the prismatic tape must be used. There are multiple grades of prismatic tapes starting with Type 4 through Type 8. Because they are so bright, there is little to no discernible difference between the various prism types to the human eye. As you move away from the tape, you will notice a difference. The further away from the tape, you need to see, the higher the type needs to be. The brightest tape I know of is the SOLAS Coast Guard approved tape. It is used for offshore applications and is critical for search and rescue operations where the victim may be about a thousand yards away.

Many ribbed tapes are too thick to CAD cut. Except for KWVINYL tape. The KWVINYL ribbed tape can be made into a thin single layer of tape. This has two advantages. First, the tape won’t layer as thicker tapes do. Second, it can be CAD cut with a vinyl cutter/plotter. This is a huge advantage. Prismatic graphics are displayed several times farther away than standard glass bead graphics. This is an obvious advantage.

Some different types of prismatic reflective tape are DOT C2 tape, FRA reflective tape, SOLAS Coast Guard reflective tape, school bus tape, and Chevron reflective strips, and sign sheeting.

All in all, glass beads and prismatic tape have their uses and will continue to make people safe and visible for years to come.

6.4 Metallized and Non-Metallized Micro-Prismatic Reflective Tape

These two types of structures are referred to as prismatic reflective tape. The prismatic tape uses an artificial prism or mirror to reflect light back to the light source. (This is different from glass bead tape that uses glass spheres to reflect light.)

6.4.1 Metallized Prismatic Reflective Sheeting

Such films are made by first creating an array of miniature prisms, then coating the tops of these prisms with a clear or colored polymer, and then metallizing the backs of the mirrors. This process completely protects the prism, so the tape can be cut in any position without compromising the integrity of the prism. You can cut letters, shapes, numbers, etc… Without having to worry about the prism being contaminated by the elements. The tape usually has a pattern on the front and is often used to make the tape more visible or vivid during the day. It’s also much thinner than non-metallic prismatic tape, so it can be wrapped around smaller diameter curves. (Snow poles, bollards, etc.)

6.4.2 Non-Metallized Prismatic Reflective Sheeting

This type of film is often referred to as reflective prismatic sheeting. The non-metallized film is made by first creating an array of prisms. This can be either transparent or colored. This layer is then laminated onto another layer that provides a white background for the top prismatic layer. These films are usually more vivid than metabolic films because they use a white background rather than a metallized mirror background. The downside is that the two later versions may be layered. It is also thicker and more inflexible. This type of film is ideal for signs and other static applications, but for automotive graphics, metallized film must be used.

Chapter 7. What is The Brightest Reflective Tape?

I get contacted all the time by people asking, “Which one has the brightest reflective tape?” The question. The quick and easy answer to this question is white or silver micro-prismatic reflective tape. SOLAS would be an example of this grade and color of tape. It is used in marine applications to help rescuers locate personnel or lifeboats. SOLAS can reflect up to 1,000 candelas and can be seen from thousands of feet away. The color version of the tape is Oralite V82 (AP1000). But brightness isn’t all that users need in a reflective film.

The better question is, “What kind of reflective tape is best for my application? In other words, brightness is only one factor to consider when choosing reflective tape. There are other very important factors to consider as well. These are color, flexibility, price, longevity, adhesion, contrast, competitive lighting, and light dispersion. As a result of these other factors, many different types and colors of reflective tape are manufactured. In this article, I would like to introduce the different types of reflective tapes and list their basic characteristics. The main focus will be on brightness, but I would like to summarize other factors as well.

In each section below, you will see how the brightness or reflectivity of a particular tape is affected by type (tape construction) and color. The brightest tape in each category is always white (silver). I also want to mention that all tapes are brighter. As you get further along you begin to notice a difference.

Note – Figure 10 shows white/silver reflective tapes in order of brightness. The left side is the least bright and the right side is the brightest. Keep in mind that brightness is not always the only consideration. For example, if you were to wrap a bike frame in reflective material, you could use the tape on the left side. (Engineer Level) This is because it has other properties that outweigh the brightness. In this case, conformability. The good news is that prices also go up from left to right. Engineer grade is very affordable, SOLAS is very expensive.

Fig.8 White/Silver Reflective Tape In Brightness Order

7.1 Flexible Engineer Grade Type 1 Reflective Tape

Engineer Grade Retroreflective Tape is a type of material with glass beads to provide retroreflectivity. It is a thin, flexible material that is molded into a single layer to prevent delamination. It comes in the widest selection of colors and is the cheapest and most popular of all tapes. It is used in a variety of applications where the viewer will be very close to the tape itself. The engineering grade is divided into standard and flexible grades. The flexible grade will stretch and is used in applications where fit is important. If you want to mark rough and uneven surfaces, then this is the tape you need. (e.g. – bicycle wraps) This material can be computer cut into letters, shapes, and numbers and is therefore widely used on emergency vehicles and signs. It is often combined with a brighter background so both colors are reflective, but still, allow for contrast. Because it is a glass bead tape, it disperses light at a wide angle. It is recommended for applications where the viewer is within 50 yards of the tape.

The estimated luminance at that level for the different colors measured at Candela is as follows.

- White – 108 Kandla

- Yellow – 88 Kandra

- Kim-78 Kandla

- Orange — 54 Kandra

- Green- 28 Kandra

- Red – 21 Kandla

- Blue – 12 Kandla

- Black – 10 Kandra

Note – There are multiple other colors for this grade. The main ones are listed above.

7.2 Flexible High Intensity Type 3 Reflective Tape

Flexible High Intensity Type 3 Tape is a flexible, stretchable version of our standard high intensity tape. It only comes in three colors, white, yellow, and orange. This tape is designed for use with traffic cones and barrels, but it is also useful for a variety of other applications where bright, stretchable tape is required. For example, helmets have an uneven convex surface and most tapes don’t meet the requirements. But flexible high intensity will.

- White – 250 Candela

- Yellow – 170 Kandra

- Orange — 100 Kandra

7.3 High Intensity Type 3 Reflective Tape

High Intensity Type 3 tape is made by laminating the layers together. The high refractive index glass beads are contained within a small honeycomb chamber with a void above. This arrangement makes the tape brighter. Although still thin, this tape is stiffer than the engineer grade. It is ideal for smooth surfaces and is about 2.5 times brighter than the Engineer Grade product. This glass bead reflective tape is used in applications that require the viewer to view the tape from an equal distance from the center. It is more expensive than the Engineer’s Grade but less expensive than Prismatic. The tape also disperses light at a wide angle. The addition of the tape increases the reflectivity and makes it light up to the viewer faster than other tapes. Cutting this high-intensity reflective film CAD into letters and shapes is not recommended. In creating sign backgrounds, wrapping posts, marking loading docks, making gates reflective, and other similar applications. Recommended for applications where the viewer is within 100 yards of the tape or in highly competitive areas.

- White – 250 Candela

- Yellow – 170 Kandra

- Orange — 100 Kandra

- Green – 45 Kandra

- Red – 45 Kandra

- Blue – 20 Kandla

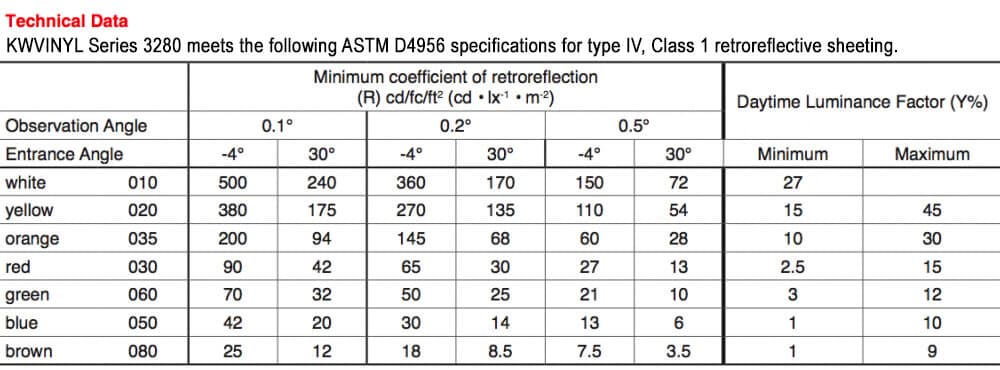

7.4 Non-Metallized Micro Prismatic Reflective Tape – Type 4 (also known as High Intensity Prismatic HIP Reflective Tape) KW-3280

The non-metallized micro-prismatic tape is made by laminating a prismatic film onto a honeycomb grid and white backing. It is similar in construction to a high-strength glass bead tape, but the air chamber is located below the prism. (Microprismatic with air support) The white backing gives the tape a more vibrant color. It is a little more expensive than high strength but cheaper than metallized micro prismatic. It is best used on a smooth surface. The film is more distantly visible than high-intensity or engineering grade film and is ideal for applications where the viewer moves away from the tape.

- White – 360 Candela

- Yellow – 270 Kandra

- Orange — 145 Kandra

- Green – 50 Kandra

- Red- 65 Kandra

- Blue – 30 Kandla

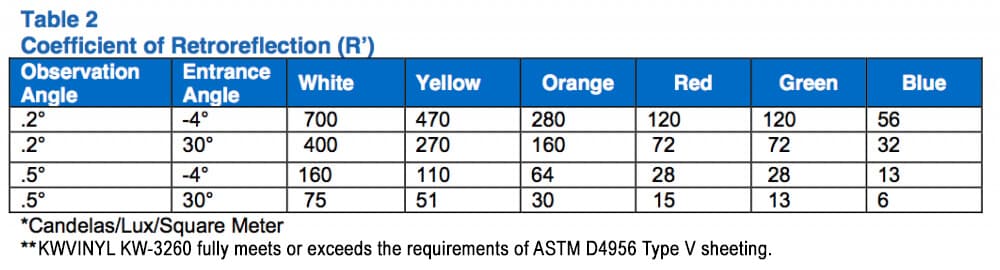

7.5 Metallized Micro Prismatic Reflective Tape – Type 5 – KWVINYL KW-3260

In terms of durability and reflectivity, the Metallized Ultra Prismatic Reflective Tape is the most important product. It’s molded into one layer, which means you don’t have to worry about delamination. This is especially good when using the tape in dynamic environments where it could be abused. You can beat it and it will still reflect. It’s made by applying a mirror coating to the back of the micro-prism layer and then coating the back with adhesive and an anti-stick liner. It costs more to make but is worth the effort. Since it is a single layer film, it can be CAD cut into letters and shapes. This material can be used for all applications, as well as applications where the viewer is more than 100 yards from the tape. In most cases, this reflective tape can be seen from up to 1000 feet away.

- White – 750 Candela

- Yellow – 525 Kandra

- Green – 130 Kandra

- Red – 130 Kandla

- Blue – 55 Kandla

7.6 KW-3240 Metallized Prismatic Reflective Tape – (compared to Type 5)

KWVINYL produces a KW-3240 metallic reflective tape very similar to the KW-3260, but slightly less expensive and slightly less bright when reflected.

7.7 KWVINYL’s KW-3265 Conformal Reflective Tape – Metallized Prismatic – (Compared to Type 5)

KW-3265 is designed for vehicle graphics and can also be cut on a plotter. I found it easier to cut than KW-3260 or KW-3240 film. It is slightly thicker and has a rubbery texture to it. It reflects in 750-candela white. It is very popular for stripping emergency vehicles and utility vehicles.

7.8 SOLAS Metallic Micro Prismatic Tape – KWVINYL SOLAS

Finally, KWVINYL SOLAS reflects over 1000 Candela. It is only available in white/silver. It has a gray-silver appearance during the day but is bright white at night. It can be seen from over 1,000 feet away in both good and bad weather conditions.

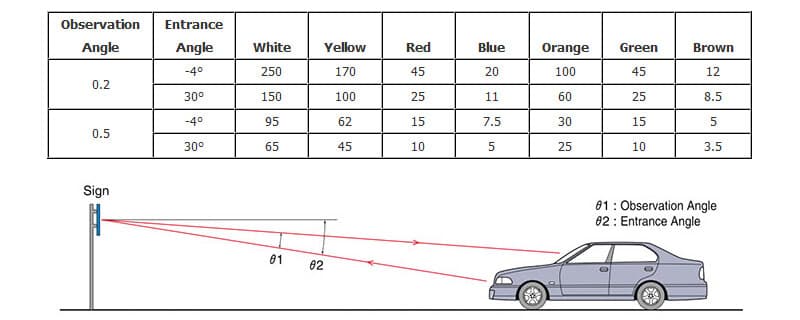

Chapter 8. Reflectance Specifications for Different Types of Reflective Tape

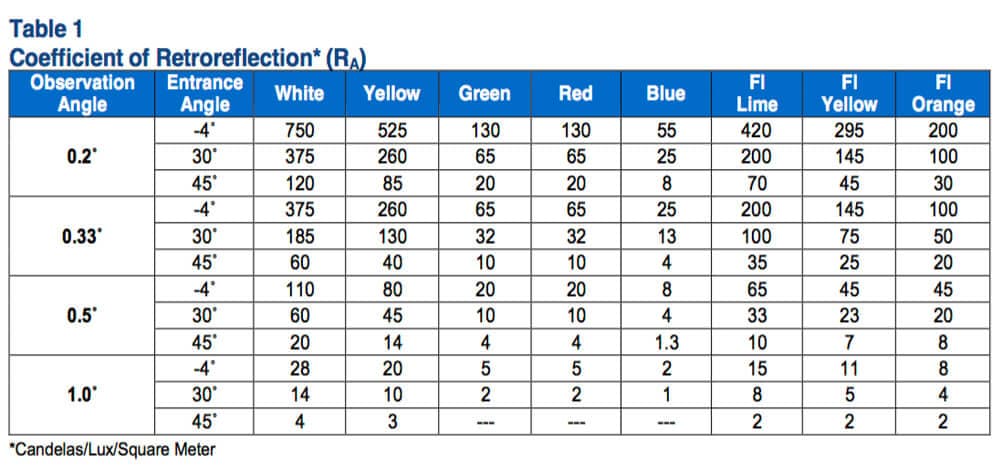

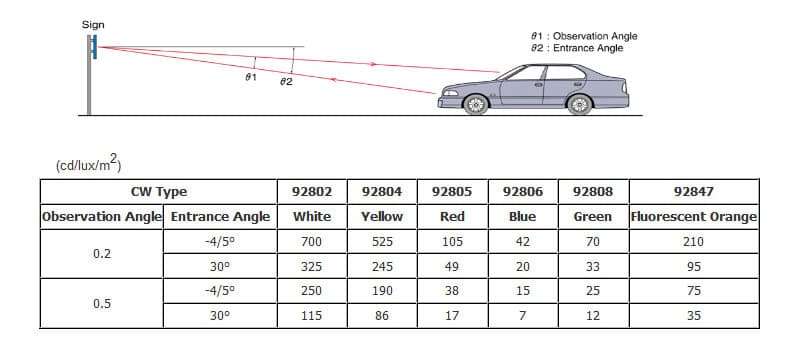

There are several types of reflective sheeting. Engineer Grade is the most common and is referred to as Type 1 film. Super Engineer Grade is Type 2. High Strength is the brightest glass bead film and is type 3. The first prism film is type 5. The brightest film is type 8 and is often referred to as crystal or diamond grade. We have charts for each film below. The exact intensity will vary by manufacturer, but the charts below are a good guide. Also, note that the Type 3 High Intensity charts also define the angle of observation and angle of incidence.

Type 1 Engineer Grade Reflectance Meter

| Observation Angle |

Entrance Angle | White | Yellow | Red | Blue | Orange | Green | Brown |

| 12′(0.2°) | -4°/5° | 108(80) | 70(50) | 21(14.5) | 8.2(5) | 54(25) | 28(9) | 5.4(1) |

| 15° | 90(55) | 64(35) | 19(10) | 7.2(3) | 56(–) | 26(3) | 5(–) | |

| 30° | 57(34) | 48(22) | 13(6) | 5(2) | 35(7) | 18(3.5) | 3(0.3) | |

| 40° | 30(11) | 30(7) | 8(2) | 2.4(1) | 20(2) | 10(1.5) | 1.4(0.1) | |

| 20′(0.33°) | -4°/5° | 83(50) | 53(35) | 16(10) | 6.4(3) | 41(15) | 21(7) | 4.2(0.7) |

| 15° | 80(45) | 50(20) | 15(8) | 6(2) | 36(–) | 20(3) | 3.9(–) | |

| 30° | 47(29) | 40(16) | 11(4) | 4.2(1) | 29(8.5) | 15(3) | 2.7(0.5) | |

| 40° | 26(11) | 26(6) | 7(2.5) | 2(0.8) | 16(2) | 9.4(1.2) | 1.2(–) | |

| 0.5° | -4°/5° | 44(30) | 33(25) | 11(7.5) | 3.8(2) | 26(13) | 13(4.5) | 1.3(0.3) |

| 30° | 34(11) | 29(13) | 8.7(3) | 3.1(0.8) | 21(4.9) | 11(2.2) | 1(0.2) | |

| 1.0° | -4°/5° | 20(5) | 16(3) | 5(1.5) | 1.8(0.6) | 11(–) | 5.3(1) | 1.1(–) |

| 15° | 19(3) | 15(2) | 4.8(1) | 1.7(0.3) | 9.2(–) | 5(1) | 1(–) | |

| 40° | 11(1.5) | 9.5(0.5) | 2.8(0.3) | 1.1(0.1) | 6.2(–) | 3.2(0.2) | 0.8(–) | |

| 2.0° | -4°/5° | 6.2(5) | 6(3) | 2.1(0.8) | 0.6(0.2) | 4.2(1.5) | 1.9(0.6) | 0.6(–) |

| 15° | 5.4(2.5) | 4.7(1.5) | 1.5(0.4) | 0.5(0.1) | 3.2(0.8) | 1.6(0.3) | 0.5(–) | |

| 40° | 4.2(1.5) | 3.8(1) | 1.2(0.3) | 0.4(0.06) | 2.7(0.7) | 1.2(0.2) | 0.4(–) |

Type 2 Super Engineer Grade Reflectivity Meter

| Observation Angle | Entrance Angle | White | Yellow | Red | Blue | Orange | Green | Brown |

| 0.2°(12′) | -4°/5° | 185.0 | 126.0 | 44.0 | 12.0 | 76.0 | 38.0 | 9.0 |

| 15° | 150.0 | 110.0 | 34.0 | 10.0 | 65.0 | 19.0 | 8.0 | |

| 30° | 100.0 | 57.0 | 25.0 | 4.6 | 45.0 | 17.0 | 5.0 | |

| 40° | 40.0 | 21.0 | 13.0 | 1.2 | 16.0 | 6.0 | 2.5 | |

| 0.33°(20′) | -4°/5° | 130.0 | 94.0 | 31.0 | 6.2 | 54.0 | 26.0 | 6.5 |

| 15° | 121.0 | 71.0 | 27.0 | 5.2 | 50.0 | 15.0 | 6.0 | |

| 30° | 90.0 | 53.0 | 26.0 | 3.4 | 20.0 | 14.0 | 4.5 | |

| 40° | 34.0 | 15.0 | 12.0 | 1.2 | 15.0 | 3.0 | 2.0 | |

| 0.5° | -4°/5° | 72.0 | 54.0 | 18.0 | 4.0 | 30.0 | 15.0 | 3.0 |

| 30° | 68.0 | 42.0 | 17.0 | 2.7 | 28.0 | 11.0 | 2.8 | |

| 1.0° | -4°/5° | 22.0 | 18.0 | 6.3 | 1.3 | 11.0 | 3.1 | 1.6 |

| 15° | 19.0 | 14.0 | 5.5 | 1.2 | 10.0 | 2.7 | 1.1 | |

| 40° | 14.0 | 7.0 | 3.3 | 0.4 | 6.8 | 1.6 | 0.7 | |

| 2.0° | -4°/5° | 9.2 | 5.8 | 3.3 | 0.6 | 3.2 | 1.4 | 0.6 |

| 30° | 8.1 | 5.7 | 2.5 | 0.4 | 2.8 | 1.3 | 0.4 | |

| 40° | 6.3 | 3.4 | 2.4 | 0.3 | 2.7 | 0.8 | 0.3 |

Type 3 High Intensity Reflectance Meter

High Intensity Prismatic Type 4 (HIP)

Type 5 KW-3260 Metallized micro prismatic reflective tape (thin tape)

KW-3265 KWVINYL Conformable Prismatic (slightly thicker than KW-3240 / KW-3260)

Type 8 Crystal/diamond reflectance meter (harder tape)

Comparison Table of Brightness or Reflectivity of Retro Reflective Tape

There are several types of reflective tape, each with different brightness, flexibility, and fitting ability. Some have a type rating similar to “Type 1 or 3”, while others do not. Typically, tapes used as signage on DOT roadways are designated as Type 1, 2, 3, 5, or 8. Tapes used in other applications are not categorized by type. SOLAS marine tape is an example. Different reflective tapes vary in brightness, but there are a number of other characteristics that should be considered. The tape you choose will depend on your application, the surface, and the distance you need to see the tape.

The table below lists the major types of reflective tapes, along with the brightness of each and any special characteristics.

- The following reflective factors are in candela and are measured at -4 degrees of incidence. These factors are approximate and are intended to be used for comparison. The following factors apply to white tape.

- To make a CAD cut means that the material can or cannot be cut using a computer-controlled vinyl cutter to create letters, numbers, symbols, etc.

- Flexibility means that the tape will bend easily. The thin, flexible tape will bend the radius more easily.

- Stretchable means it will stretch to conform to complex curves. Only flexible engineer grade and flexible high strength can do this.

| Types and names of reflective bands | Brightness (white) | Characteristic |

| Engineer Grade Reflective Type I Tape | 80-100 Kandra | Flexible but only extends a small section. Can be CAD cut. |

| Type I Flexible Engineer Grade Tape | 80-100 Kandra | Flexible and will stretch. Especially when heated. Easy to make CAD cuts. |

| Super Engineer Type II Tape | 185 Kandla | Flexible stretch a little. Can be cut by CAD. |

| High Intensity Grade Type III Reflective Tape | Kendra 250 | Flexible, will not stretch. Difficult to CAD cut. |

| Flexible high-intensity type III tape | Kendra 250 | Stretchable will stretch. Can be CAD cut. |

| KW-3240 reflective prismatic tape | 460 Kandra | Flexible, won’t stretch. Can be cut by CAD. |

| KW-3265 reflective prismatic tape | Similar to KW-3240 | Elastic will stretch slightly. Can be cut by CAD. |

| High Intensity Prismatic Type IV Tape | 500 Kandra | Flexible, won’t stretch. Difficult to cut with CAD. |

| KW-3260 Type 5 Reflective Prismatic Tape | 700 Kandra | Flexible, won’t stretch. Can be cut by CAD. |

| Type VIII CRG Nikkalite Prismatic Tape | 700+ Kandra | Harder, thicker film. It Will not stretch. Can’t make CAD cuts. Very similar to diamond grade tape. |

| SOLAS Prismatic Tape | 1000+ Kandra | Thin and flexible. It Will not stretch. Extra aggressive adhesive. Can also sew material. |

Special Reflective Tape

KW-3288 Reflective Fluorescent Yellow Tape – Thicker than KW-3240 tape, but still CAD cuttable. Reflects about 325 candelas, great for yellow negatives. For use on Chevron striped fire truck back covers.

FRA 224 Railroad Tape – School bus yellow (gold) or white. White reflects at 600 candelas, yellow reflects at 400 candelas. Flexible but will not stretch. Used to mark trams. Also known as FRA Reflective Tape.

Chapter 9. How to Reduce Rear-End Collisions – Fleets and Utility Vehicles

Reduce rear-end collisions in commercial and utility fleets. In the United States alone, there are approximately 137,500 accidents involving commercial vehicles. To put this in perspective, every 16 minutes, one person is injured or killed in an accident involving a commercial vehicle. About 50 percent of these accidents occur during the day and about 50 percent at night.

About one-third of these accidents involve rear-end collisions. These rear-end collisions are the problem our products are designed to address. The reason for the emphasis on this particular type of collision is that other types of collisions can be reduced through driver training. However, reducing rear-end collisions is another matter.

Rear-end collisions occur when a driver does not see a vehicle slowing or stopping in front of them in time. Vehicles that are frequently stopped in or near moving traffic are particularly susceptible to these types of accidents. Since most of these vehicles are commercial vehicles, the liability associated with a collision can be significant.

Increasing the visibility of vehicles is the key to reducing these accidents. Increased visibility equates to more reaction time, which in turn leads to a significant reduction in collisions. Bright, high-visibility reflective tape in a herringbone or alternating pattern has been shown to reduce accidents by as much as 41%. The effectiveness of this method has been demonstrated in the fire apparatus and emergency vehicle markets.

Chapter 10. Applications of Reflective Tape

Reflective Tape. Everyone knows where it’s used right? I’ll be honest, until I started working with it, I had absolutely no idea how many pieces I’d see of reflective tape each day. It’s a little strange since it’s the whole job is not to fade into the background but, like most things that do their job well, you kind of take it for granted.

The below is by no means exhaustive but hopefully, it proves a little useful in inspiring you to come up with your own ideas. As always if you do come up with a particularly interesting use, we’d love to hear about it.

10.1 Reflective Tape for Snow Poles and Snowy Winters

Each year, as the weather turns colder, people in the northern states of the United States and Canada begin to prepare for snowy conditions. Snowplowing companies begin making snow poles to mark roads and driveways, while snow sports enthusiasts begin preparing their trails and snowmobiles. There are various other types of vehicles and objects to check for during snowy nights and days. (I.e. dumpsters, roll-off containers, fire hydrants, utility boxes, gates, fences, etc.)

Creating visibility in the snow is always a matter of contrast. The words in this article are only visible because they are black and the background is white. In the northern states of the United States, the contrast in the summer will be different than in the snow for obvious reasons. In addition, you must also consider the visibility during the day and at night. You can see how this can be a challenge.

To keep this article simple, I will list the different colors of prismatic tapes and their advantages and disadvantages for visibility in snow. Prismatic tapes are the brightest type of tape and are perfect for snow conditions. I have a photo above of the different types.

White – This is by far the brightest of the tapes. White prismatic reflections range from 500 for DOT white to 1000 candela for SOLAS. On a dark background, this is fine, but on a white background, the visibility drops. In daylight, white is not very visible.

Fluorescent Lime Yellow – This tape is visible during the day and at night. While not as bright as white, it is very bright. About 325 candela, which is excellent. You can see it against almost any background. The advantage of this tape over white is that it reflects a color, which is important when white is the background.

School Bus Yellow- This tape reflects about 310 candela, which is very good. It is about as bright as fluorescent yellow. At night, they look similar, but during the day, fluorescent yellow is more noticeable. The tape reflects yellow, making it visible to other colors.

Orange – This tape reflects about 185 candelas. For an orange tape, this is actually very good. Orange really stands out from the other colors. It usually designates a work area so it is a good color for snow poles. The darker shades stand out against the white.

Red – This movie is a reflection of 75 Candela. Don’t let the low number fool you. Keep in mind that you will be emitting 75 red candela, which really gets noticed and does a great job on the snow. It’s also noticeable during the day. A good film for shooting snow poles.

Green-reflectivity is the same as red. Good color markers for areas that can be accessed. Green is the universal “GO” color. Stands out. Use it where green is needed.

Blue – The tape reflects 35 candelas. For blue, it’s very good. Blends well with other colors. Good light background. 35 Candela is enough to see the tape from a few hundred feet away.

Keep in mind that you can mix colors to create any desired effect. You can streak red between two whites to get good contrast. You can use green to mark areas that can be entered and red to mark areas that are not entered. Blue is usually used for fire hydrants. Yellow is the color of the working area and indicates a warning. As mentioned earlier, I recommend placing the prism tape on other types of reflective tape due to the high reflectivity.

10.2 Reflective Tape for Automatic and Manual Gates and Fences

Gates and fences are designed to block or restrict access to certain areas. Standard gates are very expensive, and automatic gates are even more expensive. Needless to say, no one wants their gate to be hit by a vehicle. This is where reflective tape can help. When marking a gate or fence, you can choose between different strengths and colors of reflective tape. You want to make sure that your gate is visible during the day, at night, up close, and far away.

In daylight, color is key. You need a bright color that draws attention to the area. Barricade tapes that are angled are perfect for getting the driver’s attention. These tapes are available in engineer grade and high strength grades. Again, they can be purchased in red/white or orange/white combinations.DOT tapes are also useful for daytime visibility. They display white and red alternately. You will see these tapes used extensively on over-the-road trucks. We also have a door arm tape that looks similar but has 16 inches of alternating colors. These tapes are like barricade tape, but the stripes are up and down instead of diagonal.DOT tape is for prism grades only. (Brightest) All of these tapes make your door very visible day and night.

If you prefer to use a single color and still want to be visible during the day, you can choose a color engineer grade, high intensity, or prism grade tape. Red, orange, yellow, blue, and green are available. Alternating colors are also an option. Engineer Grade is bright at night, High Intensity is bright, and Prismatic is the brightest.

To view at night, you can use the options above. However, you also have the option of using tape that blends in with the door. If your door is white, silver or grey, it is white engineer, high intensity, or prismatic tape will blend in and be brightest at night as well. White is always the brightest color. If you have a bronze or black door and want to blend the tape together during the day, there is only one option. That’s black engineer grade reflective tape. This tape is black during the day but reflects gold up to white depending on the brightness of the light that hits it. Keep in mind that black reflective tape reflects about 10 candelas of light, while white engineer grade reflective tape reflects about 75 candelas. Compare this to prismatic tape that can reflect 500 – 1000 candela (depending on the type). I find that black is perfect for gates in dark alleys with no competing light. If you do use black, then you will want to use it as much as possible.

In my opinion, the safest choice is DOT tape or RGA railroad gate arm reflective tape. They get your attention during the day and are very bright at night. They can be seen from thousands rather than hundreds of feet away.

If you have a legal requirement to have alternating red and white tape on your doors, you need to use our RGA (railroad gate arm) reflective tape.

10.3 Sewn To Clothing

For those of you looking to increase your visibility when exercising at night or working in areas with passing traffic, a little reflective tape sewn to the outside of jackets or shirts can be a huge help.

Though you can use our reflective tapes for this, they’re not designed for it so we don’t recommend it. You can buy reflective fabric that doesn’t have the adhesive and is a little more flexible. This may be a better option for sewing clothes.

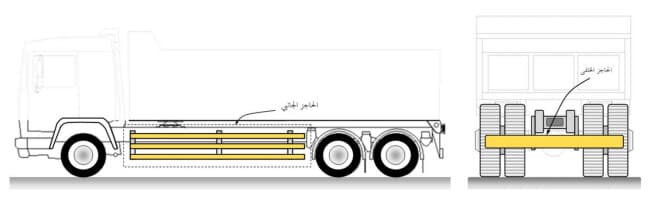

10.4 Vehicles and Trailers

One of the more common uses for reflective tape is on the sides and backs of vehicles, rolling stock, or trailers. While most of these already have reflectors, many companies and people see benefits in increasing their visibility by adding more. This can be of real benefit if the vehicle or trailer is parked in a partially obscured spot or high traffic area at night or in low light conditions.

10.5 Highlighting Objects On The Edge Of Driveways

Something I’m sure will strike a chord with anyone who has to repeatedly back out of a curved, sloped, or complex driveway; an object on the edge can be a real hazard. Especially things with a narrow profile (like handrails) as these can be hard to spot in your rear-view mirror and parking sensors don’t always pick them up.

If your driveway has things like this on its edges, it could well be worth placing a little reflective tape on them to increase their visibility at night. Of course, you’ll never need them but it could make life a little easier and save some serious embarrassment next time you have people around for a barbeque.

10.6 Bikes and Motorcycles

Most come with some reflectors. But in our experience, a few extras can’t hurt. Just be sure that you affix the reflective tape so that you are not obscuring or obstructing any critical component. Every state’s regulations are slightly different on this point so it may well be worth checking first.

10.7 Letterboxes

If your letterbox sits particularly close to your driveway or is in an area where it may be obscured by surrounding gardens, a little reflective tape placed at strategic points can significantly increase its visibility. This can be particularly useful in raising its profile for visitors who may park in your driveway, then have to reverse out after sunset.

10.8 Reflective Tape Applied To Bike/Motorcycles Helmets

If you’re planning on riding at night, a couple of reflective spots on your helmet can significantly increase your visibility.

10.9 Boats and Ships

Reflective tape on the topside, sizes, and underside of your craft can make a big difference to visibility and safety. Obvious placement points include out-jutting parts and on protruding edges (though low doorways may also be worth thinking about as per point ???). One area you may not have thought of is the underside of the boat. If the worst does happen and the craft is overturned, an aerial search will be easier if there’s some reflective tape in place to help catch the searcher’s attention. This is particularly pertinent for life rafts and smaller vessels.

10.10 Life Jackets

Many come with reflective strips already attached but like my point about bikes, depending on the make it could be worth augmenting this with a few strategically placed extras.

10.11 Sewn To Children’s Bags

Especially if they’re walking to or from school in winter, a little reflection can increase visibility to cars and other vehicles. You won’t need much for this to work, just a few small squares or a single strategically placed strip should have the desired effect.

One tip with this, ensure you choose a Reflective Tape that contrasts in colour with the bag. I.e. White Tape for a red bag is better than a red on red.

10.12 Bollards and Posts

This is one of the most common uses for Reflective Tape already so I won’t spend a lot of time covering it. Especially when they are installed in low-light areas (like underground car parks), increasing the visibility of bollards, safety rails, support posts, and pillars by placing some reflective tape on/around them can make a lot of safety sense.

10.13 Ledges and Steps

Highlighting sudden drops or rises on the ground is a great use of reflective tape. A narrow strip on the edge of a step can significantly raise awareness and help prevent tripping or the potential for falls.

In these applications, it is very important to ensure that the tape is applied smoothly without any bumps or raised edges. Choosing a tape with a strong adhesive will help with this. You should also prioritize abrasion resistance. No matter if you choose to place the tape on the flat or vertical part of the step, it will see some abrasion from people walking on it, so a tape with higher abrasion resistance will last longer.

10.14 Low Hanging Objects

Whether at home or in the workplace, a little reflective tape can go a long way in increasing the visibility of low doorways, objects, and clearances. These can include entryways to garden sheds, garage doors that are sometimes kept at half-height, or pipes that run across walkways.

At home, this can help avoid head injuries or accidents. In the workplace, this can be especially important if a forklift is operating. Garage doors are a definite hazard if they are kept half-way down (say, to stop rain blowing in) and a forklift operator is used to having full clearance when passing through. In such situations, anything you can do to increase awareness and visibility of the potential hazard may well prove worthwhile.

10.15 Witches Hats / Safety Cones

Safety cones, witches hats, traffic cones; there are a few different names for them and even more styles available. Most are made in highly visible colours, and many already come with retro-reflective sheeting applied, but not all.

For those styles that do not come with the reflective already in place (or if the original reflective has worn away) replacement is easy. A band of reflective tape wrapped around the cone towards the top will significantly increase the visibility and therefore the effectiveness of the safety cone. Generally speaking, we’d suggest choosing a reflective tape that contrasts in colour with the cone but this choice is, of course, up to you.

10.16 Warehouse Floors

Reflective Tape can be a highly effective and highly visible way of marking out either safety areas or hazards in factories or warehouses. Clearance zones around high voltage equipment, underneath drop hazards, and delineating emergency exit paths are just three potential applications.

Just to be clear, I’m not suggesting using reflective tape to mark out all general laneways in a warehouse. Chances are, it’d be overkill for this task and a far more expensive option than something like our Reflective Warning Marking Tape. But for highly critical areas, or when used in conjunction with vinyl tape to attract added attention, reflective tape can be very useful.

Chapter 11. How to Install Reflective Tape – Troubleshooting, Removal

11.1 Installing Reflective Tape is a Very Simple Process

Basically, it’s a peel, stick, and press process. However, some preparation must be done beforehand to ensure long-term use. The bonding properties depend almost entirely on the surface finish.

There are a number of factors to consider before installation begins.

- First, it is up to the installer to determine if the surface to which the tape will be applied will accept an adhesive-type tape. For example, some plastics are non-stick and difficult to apply. Also, since the tape does not touch the entire surface, it is difficult to apply a rough surface.

- Second, the newly sprayed surface should be fully cured before the tape is applied. Otherwise, the gases from the cured coating will deteriorate the adhesive and cause application failure.

- Third, do not use the tape in cold weather or allow it to freeze. This will damage the adhesive. After installation, the tape needs to cure for at least 48 hours before it can withstand subzero temperatures.

- Fourth, when installing Flexible Engineer Grade Tape, remember that it is temperature sensitive during installation. (It will not be affected by temperature after installation). The tape hardens when cold. It is very flexible when hot. The recommended application temperature is 59 – 77 degrees. (See below for special instructions for this tape)

11.2 Instructions for Use of Reflective Tape

The surface should be clean and dry on the outside. Do not use it in rainy or humid conditions. Sunny days are the best. The air temperature should be between 32 and 100 degrees. Again, it helps to apply a small piece first in the practice.

11.3 Clean the Surface

The surface on which the tape is placed must be clean, dry, and free of all contaminants such as dirt, grease, oil, etc. This can be done by washing the adhesive area with soap and water.

Alternatively, to ensure that the area is clean, you can wipe the surface with a cloth soaked in isopropyl alcohol. Before the alcohol dries, wipe the surface again with a rag. This will also help dry the surface and ensure that the adhesive on the tape will penetrate the surface and form a good bond.

11.4 Adhesive Reflective Tape

When applying the retro reflective tape, peel off the material lining. Do not peel off the peel ability more than once and do not allow it to stick to you. Also, avoid touching the adhesive side of the tape, as oil on your hands can contaminate the adhesive and reduce its effectiveness.

Use your fingers to lower the material onto the surface. Try to avoid putting the tape down, then pulling it up, and then putting it down again, as this can deteriorate the adhesive.

Use a suction pick or similar object to press the tape against the surface. Apply pressure gently first, then apply more pressure. This will force the adhesive into the holes on the surface. If necessary, wrap the skimmer in a cloth to avoid scratching the material. If you do not have an absorbent stripper, press the tape firmly onto the surface with the cloth. For seams, use a razor blade to cut the material. Inspect the rivet and then cut it with a razor or large knife after application so that the material is always flat around the rivet. Note – In most cases, our flexible engineer grade will outlast the rivet.

Our flexible engineer grade and flexible high-intensity tape will go around corners and fold over the edge of the door, however, our other reflective tapes are tougher, will not stretch, and will not wrap around sharp corners or fold into 90-degree edges. If going around a sharp corner, cut the tape and start a new cut at the corner. The edge of the tape should stay about 1/4 inch from the edge of the surface to be treated. If you bend the rigid tape around a sharp corner, they will stick first but will eventually roll up. The material is designed to be applied to generally flat surfaces. As mentioned earlier, for complex curves, use our Flexible Engineer Grade or Flexible High Strength Grade tapes.

Special Instructions for Flexible Engineer Grade Tapes – Operating Temperature – 59 – 77 degrees Fahrenheit. Within this range, the tape performs like a standard bonded vinyl. At temperatures above this range, the flexible engineer grade material becomes very soft and pliable. When the temperature falls below this range, the material hardens. (Design the material in this manner so that the material can be heated with a hairdryer during application if necessary to conform to complex curves. rivets. etc.) The material can be installed at temperatures above and below the recommended range. It is easier to install in the recommended temperature range.

If the tape is to be installed in a hot or cold environment, it can be left in an air-conditioned or heated vehicle until it is ready for installation. During the summer months, it is best to install in the shade, while during the winter months, it is best to install in direct sunlight. In addition, we’ve posted some pictures of how to place and apply tape using masking tape hinges. In warm weather, this method will help in installing flexible engineer grade tape.

Service Temperatures – Once installed, the tape can withstand temperatures from -22 to +176 degrees Fahrenheit.

11.5 Tear-Off the Reflective Tape

Some reflective tapes are easier to remove than others. However, the process of removing them is the same. First, use a hairdryer or heat gun to heat the reflective tape. If you use a heat gun, be careful not to use too much heat as it may damage the substrate. When heating, try to gently tear off the tape. Some of the tapes will fall off all the way, and some will shatter into pieces. You can use a razor blade if you wish, but be careful not to get into the substrate. If using a razor blade, I recommend you lubricate the area with WD40. After removing the tape, cover the area with an adhesive remover (such as Goo Gone or Goof Off). Wipe off or scrape off any residue. Then clean with soap and water or another cleaner.

Chapter 12. Retro Reflective Tape Manufacturers Company Profile

KWVINYL is a reflective tape manufacturer, an industry, and a trading company. We have over 10 years of factory experience in reflective safety tape and visibility enhancements. Welcome to our “All about Reflective Tape” website. To purchase reflective tape, you can contact us by filling out the form on our website, or email it directly to our email: info@kwvinyl.com, or of course you can contact us via social media (WhatsApp/Skype).

For decades, reflective tape has played an important role in enhancing visibility and safety at night. Since its invention in the 1930s, it has saved countless lives.

Reflective tape or reflective sheeting is also known as a retro-reflective because it collects light and returns it to that light source. In other words, no matter which direction the light comes from, the reflective material collects it, focuses it, and returns it back to the light source. (Usually a car or a flashlight) This can be done by a glass sphere that acts as a parabolic mirror or by an artificial prism that reflects light back to its light source. In the above chapter titled “How Does Retro Reflective Tape Work” we show you how the tapes do this.

Retro-reflective tapes are used voluntarily all over the world so that objects can be seen at night. There are also regulations that require the use of retro-reflective tape in certain situations. These include.

What exactly is the difference between reflective and retro-reflective? The biggest clue is the word “retro” which helps us to know and understand the difference between these two reflective surfaces. When you think of reflective, think of a mirror. Where a retroreflective surface is like the reflector you would find on something simple, like a bike reflector. To understand what “Retro” is, let’s look at a definition: “retro denoting an action that is directed backward.” When it comes to reflective tape, it is defined as returning the light back to where it originally came from. So let’s go back to our mirror example. Mirrors are reflective because they emit light in different directions depending on the angle of the entrance. This wouldn’t be a good use for a protection worker if it were a high visibility suit. To explain this better, if you think back to when you were a kid, you threw a ball at a wall. The ball would bounce back, but at the opposite angle to where it came to the wall. See the example below: What does Retroreflective Mean? Now, in the retroreflective example, the light travels in and back out, to and from the same point. There are two basic types of retroreflective surfaces: glass bead surfaces and prismatic surfaces, both of which reflect light differently. Glass Bead Reflective Surfaces use glass spheres to collect light and bounce it back to the light source. The rounded shape of the glass bead is what creates the retro-reflective surface. Prismatic Reflective Surfaces do the same, but they are angled as sharply as a prism. They work in the same way as glass beads, but are more efficient, resulting in a brighter return of light.Reflective vs. Retroreflective

What does Reflective Mean?

What is DOT C2 Reflective Tape? -Definition of Specifications and Certification

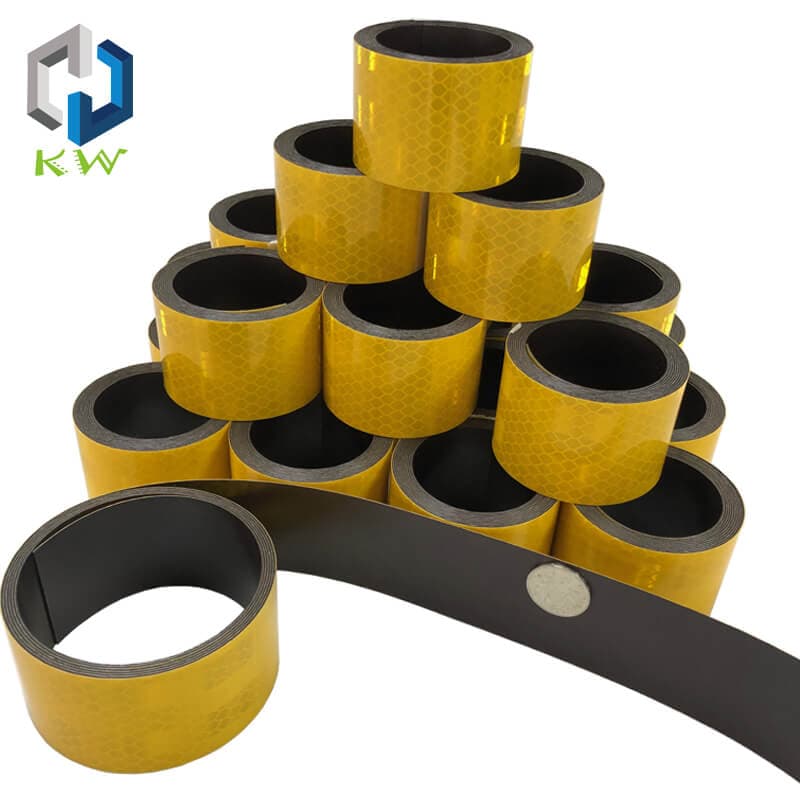

FMCSA set DOT truck (tractor-trailer) marking requirements to help improve visibility in low light conditions and to reduce the likelihood and condition of a fatal vehicle crashing into the side or rear of stopped or parked trucks and tractor-trailers at night or in poor visibility conditions.

On December 10, 1992, the National Highway Traffic Safety Administration (NHTSA) issued its Final Determination, which required that trailers manufactured on or after December 1, 1993, with an overall width of 80 inches or greater and a gross vehicle weight rating (GVWR) of 10,000 pounds be equipped with devices to make them more visible on the roadway, both on the sides and in the rear. NHTSA The regulations allow trailer manufacturers to install red and white vintage reflective tape or reflectors or reflectors. This tape is commonly referred to as DOT C2 reflective tape and is therefore marked for easy identification (exempt – pole trailers and trailers designed for living or office use).