Heat Transfer Vinyl Rolls Wholesale Suppliers Manufacturers – KwVinyl

KwVinyl is a wholesale manufacturer of heat transfer vinyl rolls. We offer heat transfer vinyl wholesale, and we can deliver the products you need directly to your company or any address you specify for delivery.

KwVinyl is a wholesale manufacturer of heat transfer vinyl rolls. We offer heat transfer vinyl wholesale, and we can deliver the products you need directly to your company or any address you specify for delivery.

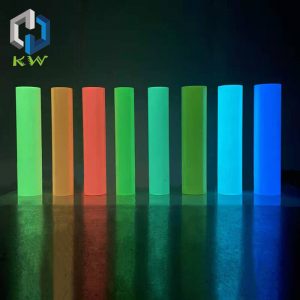

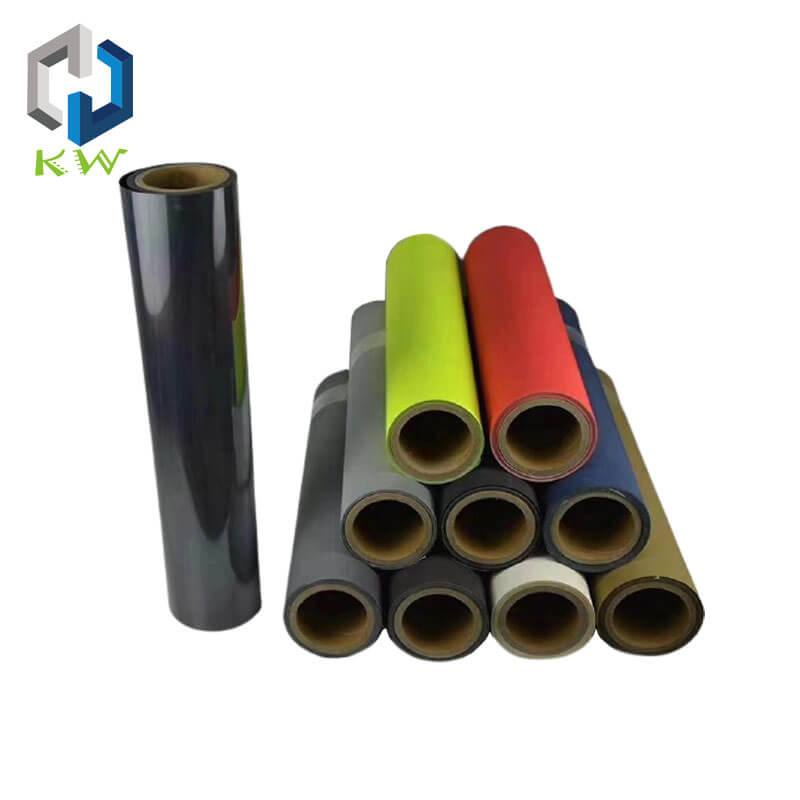

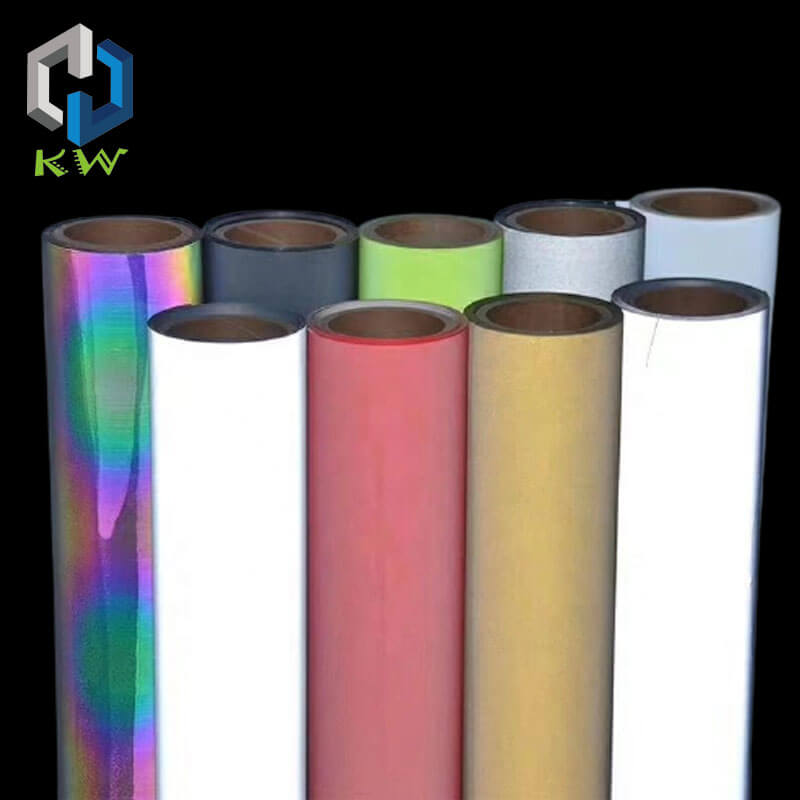

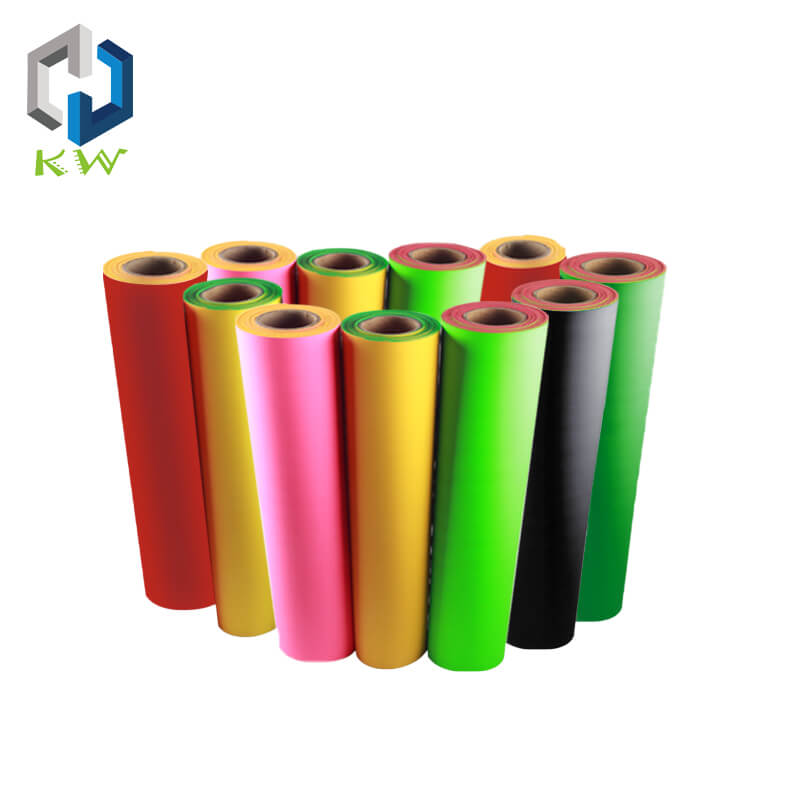

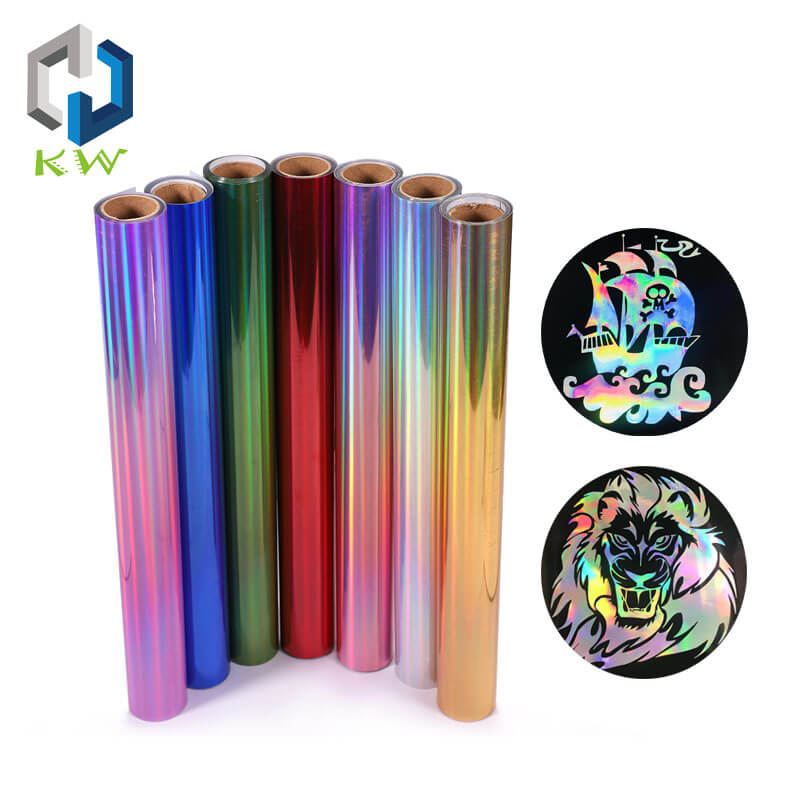

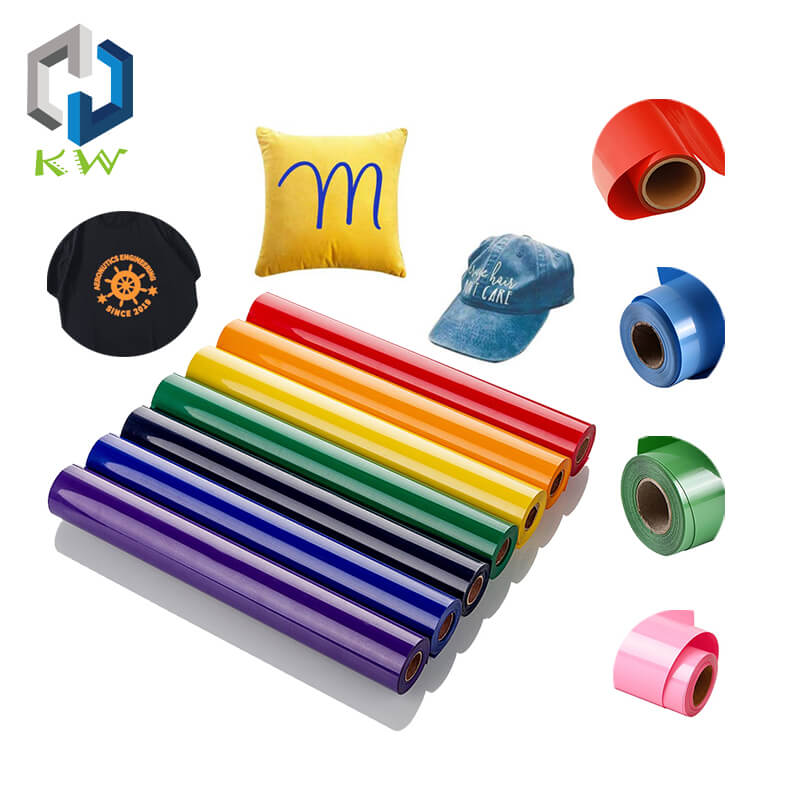

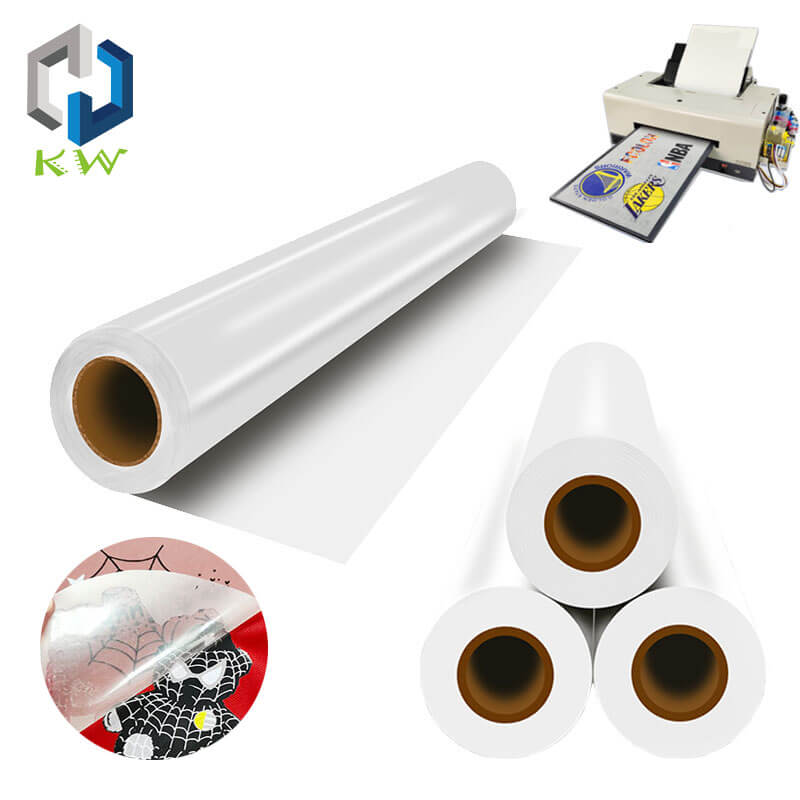

Our main product includes printable heat transfer vinyl, High Reflective Silver Heat Transfer Film, Transparent Luminescent Film, Patterned Heat Transfer Vinyl, Reflective Heat Transfer Vinyl, Glow In The Dark T Shirt Vinyl, 12 inch heat transfer vinyl rolls wholesale, Heat Transfer Printing, Rainbow Reflective Heat Transfer Vinyl, heat transfer vinyl for shirts, Orange Reflective Vinyl, PU Heat Transfer Vinyl, Glitter Heat Transfer Vinyl, Reflective Glow In The Dark Vinyl, and so on.

We also accept OEM/ ODM orders, custom reflective logos, or make your own photoluminescent logo from the KwVinyl company, Now!

Choose us, our factory wholesale HTV vinyl can save you a lot of money.

Contact us to know more details, Immediate.

If You Are Interested In Any Of Our Products Or Would Like To Discuss A Custom Order, Please Feel Free To Contact KWVINYL and Ask For A Quick Quote, Now!

Let’s get right to the main subject of this guide.

Chapter 1. What is Heat Transfer Vinyl

Heat transfer vinyl, also known as iron-on vinyl, t-shirt vinyl, heat transfer film, thermal transfer paper, or HTV, is a special type of vinyl that adheres to the fabric. This differs from sticky vinyl sheets and films, which are sticky from the start. The adhesive on the vinyl is heated. This vinyl is available in sheet, roll, and package form. When you receive the vinyl, there is both a front and backside. The front side is the shiny side – the shiny layer is a carrier sheet that can be peeled off after the ironing project. The backside is the matte side, the side that will be cut when the design is created. It is also the side that has a heat-activated adhesive. With HTV, you can transfer your creative design onto a range of surfaces. Matching the vinyl to the surface you are going to use is critical. Each manufacturer should list HTV compatibility in the product description.

Chapter 2. Heat Transfer Vinyl Applications And Features

Heat transfer refers to the use of heat pressure to transfer the heat transfer logo/label/decals/stickers onto the surface of the workpiece. Currently on the market with heat transfer vinyl many products, in addition to common clothing, shoes, and hats, as well as dishes, buildings, promotional items, cars, models, etc. ……

The characteristic of heat transfer vinyl is that the printing material will not be like sublimation dye that will produce vaporization, this kind of printing material will not because of the high pressure and high temperature cause the slurry to penetrate into the fabric fiber inside, although the same can use the transfer machine press ironing, but “printed” to the surface of the clothes will be like plated a layer of membrane, attached to the surface of the clothing.

To understand the heat transfer film will have to know its substrate, heat transfer hot ironing substrate is mostly with PET material, are printed on the PET sheet above a variety of colors, but also need to be coated in the pattern back hot melt glue, it is because of this hot melt glue can be the clothes with the pattern firmly locked together, after tearing the PET waste film, before the completion of the transfer process.

The advantages and disadvantages of heat transfer vinyl are also very obvious, the disadvantage is that if the pattern is larger printed on the clothes permeability will be poor, the feel is not as soft as heat sublimation, the advantage is that the pattern level is a full, beautiful color, low-cost plate making.

Many customers like to put their favorite movie classic picture printed on the clothes or cup! The colors of heat transfer film are very bright, UV resistant to rain, corrosion-resistant, acid and alkali resistant, clear patterns, and generally do not fade.

Chapter 3. What Is The Composition Of The Heat Transfer Film?

- 1. The base layer: that is, the release layer, printing layer, adhesive layer of the carrier – thermal transfer membrane, thermal transfer membrane, including pet film, opp film, PVC film, etc., you need to select the corresponding base film according to the needs of the specific product, otherwise it will affect the quality of the thermal transfer product.

- 2. Release layer: is a layer of release agent coating, at room temperature to maintain a solid-state, at a certain temperature can be melted, and the base layer of adhesion becomes smaller, can be quickly detached from the base film, no adhesion residue.

- 3. The printing layer: the layer is the design of thermal transfer products that reflect the aesthetics of the fundamental, the key lies in the choice of thermal transfer ink and collocation, the thermal transfer process is complete, only the printing layer is left attached to the surface of the thermal transfer products, so the choice of printing layer material is particularly important, a slight lack of attention will affect the quality of thermal transfer products.

- 4. Adhesive layer: its actual composition is a kind of hot melt adhesive. According to the different substrates, choose the corresponding thermal transfer glue.

Adhesive Layer – Hot Melt Adhesives for Heat Transfer Vinyl

How exactly do you use a hot melt adhesive film?

How do you use hot melt adhesive film? Hot melt adhesive film is actually a double-sided adhesive. With superb bonding properties, it’s also very washable and has become the darling of many heat-resistant textiles!

TPU hot melt adhesive film has advanced international coating process, the product has a super bonding fastness, not only high elasticity but also washable, belongs to the best environmental protection products, hardness is also very wide, adhesive area, suitable for a variety of high-temperature requirements, elasticity is also quite durable, not only feel good but also can keep the clothing for a long time without deformation.

So how to use this hot melt adhesive film? Actually, all industries use them differently!

For example, in the sports shoe industry, customers can first see whether the material used is fabric or leather according to the sample shoes, then heat transfer the hot melt adhesive film onto the surface of the material through high temperature laminating equipment, and after drying, electro-engrave or punch each part according to the sample, and remove the release paper of the adhesive film, and finally iron it onto the surface of other fabrics by high temperature and pressure.

In the garment industry, according to the size requirements of the bonded fabric, the customer should first cut the hot melt adhesive film into corresponding widths, and then laminate the hot melt adhesive film on the surface of the fabric by high-temperature embossing, then remove the release paper of the adhesive film after drying, and then laminate again according to the temperature required by the process, this method is what we call hot ironing seamless bonding.

Chapter 4. Characteristics Of A Quality HTV

Not every user requires the same features for their HTV. What you need depends on your project and expectations. The following are some typical features to consider before purchasing.

- Surface compatibility

- Easy to use, e.g. cutting and weeding

- Super thin, unless looking for a different effect

- Perspective grid pattern as a guide

- There’s no sticky extra gum to contend with

- Durable (resistance to cracking and peeling)

- Available in a variety of colors

- Soft to the touch

- Highly pressure-sensitive

- Clothing can stretch naturally

- Durable and washable

Chapter 5. Heat Press Transfer Process Introduction

The heat press transfer process is a process of transferring the decorative pattern on the heat transfer film onto the surface of the decorated fabric by heating the film at one time and forming the pattern on the fabric.

In the heat transfer process, the use of heat and pressure of the common role of the protective layer and the pattern layer from the separation of the polyester substrate, hot melt glue so that the entire decorative layer and the substrate permanent bonding.

The heat transfer film is made of polyethylene film liner paper with a reflective, luminous, rainbow, holographic, shining star, and other decorative layers. The surface is coated with a protective layer, a primer layer, a release layer, and a hot melt adhesive layer.

By heating the high-temperature silicon roller and applying the temperature and pressure to the transfer foil, the transfer layer consisting of decorative layer, surface protection layer, and primer layer is separated from the polyethylene and transferred to the fabric, which forms the decorative surface pattern and gives the surface excellent performance such as reflective and luminous, with novel and beautiful pattern and stable color tone.

Advanced HTV should not perform any of the following operations.

- 1. Easy peeling

- 2. Rapid disappearance

- 3. Cracking after several washes

- 4. Foams

Sometimes, especially in novices, user error is blamed on stripping, blistering, and melting.

5.1 Introduction to Heat Press Transfer

5.1. 1 Heat Press Transfer

Heat transfer printing is a new method of printing patterns on products made of various materials and is particularly suitable for producing small quantities of a wide variety of personalized and customized products, as well as for printing patterns containing full-color images or photographs.

It is based on the principle of pre-printing color patterns on a heat-resistant substrate film (through the release process), and then with a piece of dedicated transfer equipment, by means of hot ironing, high temperature, and high pressure to accurately transfer the pattern to the surface of the product, to complete the printing of goods.

Can be in leather, textile fabrics, plexiglass, metal, plastic, crystal, wood products, coated paper, and other materials on any relative plane, one-time multi-color, any complex color printing.

Heat transfer process quality and reliable technical stability, good material formula, and equipment of close cooperation. The characteristics of the thermal transfer process: simple operation, fewer production processes, high efficiency, no pollution, occupies an area of small, less investment.

After printing, good adhesion, high gloss, clear graphics, accurate color register, bright colors, safe, non-toxic, and hot ironing can be sandblasted, secondary injection molding, bending, punching, and other post-processing processing.

5.1.2 Thermal Transfer Process Classification

Thermal transfer printing methods, divided into transfer film printing and transfer processing.

(1) The transfer film printing adopts dot printing (resolution up to 300dpi), the pattern is pre-printed on the surface of the film, the printed pattern is rich in layers, bright colors, ever-changing, small color difference, good reproducibility, can achieve the required effect of the design pattern, and suitable for mass production;

(2) Transfer printing processing through the thermal transfer machine a processing (heating and pressure) will transfer the transfer film on the exquisite design transfer in the product surface, after molding the ink layer and the product surface into one, vivid and beautiful, greatly improving the product grade.

5.1.3 The principle of the heat transfer process

Pre-print the color pattern on the heat-resistant substrate film (through the release treatment), and then with special transfer equipment, to transfer to the surface of the product by hot ironing, thermal transfer process quality, and reliable technical stability, good material formula, and equipment in close coordination.

5.1.4 Heat transfer process advantages

Simple printing, no damage, accurate positioning, professional use, multiple printing

- Thermal transfer is a dry process, a single-stage process that does not require adhesives to complete the job.

- Heat transfers are excellent for decorating the edges of parts, panels, and even edge band finishes.

- Heat transfer gives the product not only the look but also the feel of real wood.

- The performance of thermal transfer coatings exceeds that of typical finishes.

- The adhesion of the decorative layer to the substrate is seamless so that the gaps are almost invisible to the naked eye.

- Parts can be immediately transferred to the next process after thermal transfer.

- Overtraining is possible on the thermal transfer layer.

5.1.5 Types of Heat Transfer

5.1.5.1 Hot Peel Heat Transfer

Hot peel is one of the most popular transfers. When used on shirts, it has the same soft texture as direct screen printing. The reason why it is called “hot-peel” is that when the transfer is applied, the paper is quickly peeled off by a hot press for 10 seconds, and the ink is split in two. One part of the ink will be transferred to the shirt, while the other part will remain on the paper. This gives the transfer a soft texture.

5.1.5.2 Cold Peel Transfer

Cold peel transfer printing also remains popular, mainly for sportswear and for foil printing on shirts. In fact, if you do it right, transfer printing can be done either by a hot peel or cold peel.

There is no difference in effect or operation between hot release and cold release. The real difference is in the paper used and the application of the press. When you use the cold peel, the transfer paper is cooled for about 30 seconds before you peel the paper off. This operation leaves the ink completely on the garment and gives the transferred pattern a very flexible, rubber-like texture.

Cold peel prints are generally not suitable when printing larger designs on t-shirts, as they are hot to wear and affect the breathability of the shirt. They also cannot be washed, as the rubber layer at the top of the ink will crack. Then, the cold peel is making a comeback as a “vintage” type of print and is being used again.

5.1.5.3 Inkjet Transfer

Inkjet is commonly used for direct printing shirts and for making transfer prints. Transfer inkjet is a special ink that is automatically ejected under high-temperature pressure.

5.1.6 Heat transfer printing method

There are two types, one heat sublimation transfer, and one heat set transfer.

5.1.6.1 Heat Sublimation Transfer

Screen printing or gravure printing of a paste produced with sublimation disperse dyes on printed paper, followed by transfer of the image on the printed paper to the desired medium.

5.1.6.2 Heat Set Transfers

Using heat-set inks, also known as heat-melt adhesives, the designs on the printed paper are transferred to products such as cultural shirts and garments after being screen-printed onto the paper.

The difference between the two methods is that the sublimation transfer method is mainly used on synthetic fabrics and hard materials coated with heat transfer coatings, while the heat set transfer method is mainly used on cotton products.

The texture of the two ways is also different, heat sublimation pattern transfer does not change the original texture of the material after the transfer, feel, and feel good. Heat-solid pattern transfer in the adhesion of the surface to form a layer of gelatinous material, feel poor, not breathable. The two printing methods in the production of each have their own advantages and disadvantages, each has its own characteristics.

5.1.7 Thermal transfer process application industry

The heat transfer process is mainly used in clothing, cosmetics, toys, plastics, food packaging, electrical appliances, stationery, and other industries, as well as a variety of wood, metal products, and other product surfaces.

5.2 Understanding Thermal Transfer Types

It is vital to pick a sound heat transfer manufacturer and learn the methods of transferring the various types of fabrics you are decorating. Additionally, get to know the customer service representatives who will assist with explaining illustration choices, pricing, and picking the best heat transfer method for any given job. Consult other garment decorators for recommendations before selecting a heat transfer vinyl supplier. Ask them to evaluate the quality of the product, customer service, and delivery. Remember, if you are getting a quality product, strong technical support, and fast delivery, it’s not a bad idea to pay a higher heat transfer fee.

The following descriptions summarize the most common types of heat transfers used by today’s garment decorators, and equally summarize the application guidelines. Please always use the application guidelines of the transfer manufacturer of the product used.

5.2.1 Cold Peel Heat Transfer Vinyl

Cold Peel Plastisol: These heat transfer sheets have been in use since the 1950s and the prints have a semi-gloss appearance and are still widely used today for team sportswear decoration and general purposes. They should be applied at 350 degrees Fahrenheit for 15 seconds at medium pressure and peeled off after the garment has cooled. After pressure is applied, a fabric wipe is used on the back of the paper to help absorb heat and speed up the cooling process before peeling. In some large stores, garments are heat pressed and set aside, and the transfer paper is then peeled off to help speed up production.

5.2.2 Hot Peel Heat Transfer Paper

Hot Peel Plastisol: These heat-release vinyl apply heat and the paper can be peeled off immediately without waiting for the garment to cool. Some heat release transfer sheets are coated with a powder binder on the back to speed up the transfer process. General application guidelines call for a fixed pressure of four to six seconds at 365 degrees Fahrenheit before heat is applied.

5.2.3 Thermal Separation Heat Transfer Film

Thermal Separation Plastisols: These heat transfer sheets were developed in the 1980s to provide a soft touch, matte surface that revitalized the heat transfer market. This looks similar to direct screen printing and is popular with retailers due to the soft feel of the print. Thermal separation transfer sheets are ideal for rosette materials, ternary blends, and women’s garments where a soft feel is required.

General application guidelines call for applying a fixed pressure at 365 degrees Fahrenheit for eight to ten seconds before heat is dissipated. After applying heat pressure and peeling, some ink remains on the paper, but most of it is transferred to the garment.

5.2.4 Heat Transfer Vinyl for Performance Garments

Heat transfer for performance garments: This type of transfer is fairly new to our market and therefore requires consultation with the manufacturer of the type of fabric being decorated. Not all manufacturers have a transfer method suitable for polyester fabrics, so research and choose a company with reliable products.

Special additives mixed with transfer inks are used when decorating show wear to give them better stretching properties and promote fabric adhesion. Some transfer sheets can be applied at lower temperatures to reduce the possibility of dye migration.

5.2.5 CAD-CUT Heat Transfer Vinyl

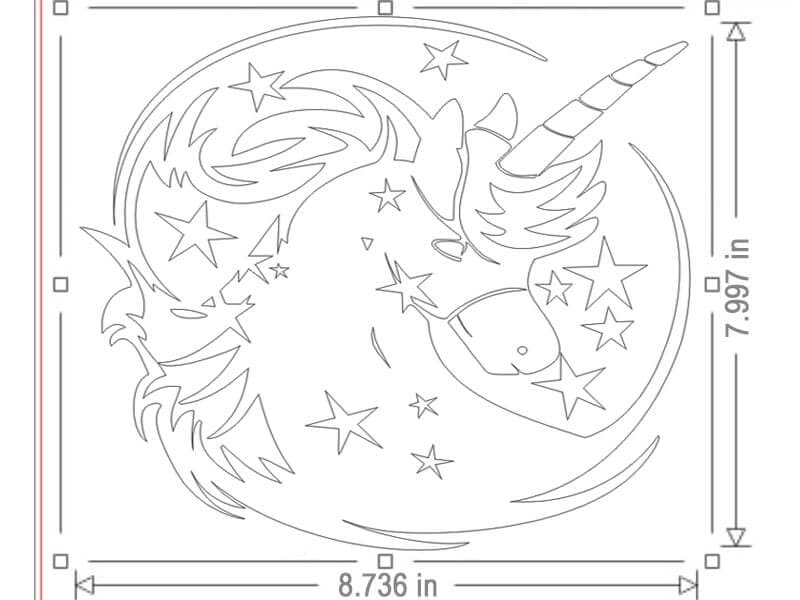

CAD-CUT Heat Transfer: These transfer materials offer a wide range of heat transfer options, including vinyl, cotton shavings, glitter, and others, and are a game-changer for some garment decorators. CAD materials are designed and cut with digital CAD cutters and heat is applied directly to team uniforms, hoodies, and t-shirts, and is an interior decorating service.

Improvements in CAD materials have made it possible for decorators to design and apply custom patterns to a wide range of polyester materials, including garments with compression effects. Consult your CAD company supplier for the type of fabric you will be decorating.

5.2.6 Sublimation Heat Transfer Vinyl

Sublimation Transfers: These transfers apply heat to 100% polyester fabrics. They are popular because they can be made at home using inkjet printers and special sublimation papers to illustrate designs in the RGB color space.

General application guidelines call for medium pressure at 390 to 400 degrees Fahrenheit for 30 to 40 seconds. Quickly remove the paper to avoid “ghosting” around the image. It is important to remember that the sublimation transfer is heat transferable and should only be used on white or colored polyester fabrics.

5.3 Usage parameters

Heat transfer films have unique properties that require a strict understanding of the optimum temperature, pressure, and speed to obtain the desired ironing results. It has three strict process parameters indicators.

1. The determination of the temperature: the temperature is too low will appear ironing not or ironing is not firm, but also make the imprint hair flower; temperature is too high and will make the chromatic surface oxidation so that the product loses luster, color darkening, serious will blister. To determine the best ironing temperature should consider the following factors: pressure, speed, area, room temperature, etc.. Ironing temperature in the general range of 140 ℃ -180 ℃, once the best temperature is determined, should remain constant, temperature difference in ± 2 ℃ fluctuations is appropriate.

2. The determination of pressure: ironing pressure is generally 4-6 kg/cm². Pressure hours, cannot make the ironing film and substrate adhesion, reduce the fastness; if the pressure is too high, and will produce substrate compression deformation increases, causing the pattern deformation, the layer of thinning. If ironing complex uneven products, more attention should be paid to the uniformity of each pressure point, the ironing wheel and the pressure angle of the substrate requirements are higher, otherwise, very easy to appear part of the fastness, part of the phenomenon of not fastness.

3. The speed of the determination: should be based on the ironing area to determine, at the same time to consider the power of the heating temperature. General is the first speed, then determines the pressure, and finally determines the temperature.

5.4 The importance of weeding

Mowing is a process that takes some practice to perfect, but what is it? It is the removal of excess vinyl from around and inside the decal. There are a variety of weeding tools for this purpose, the most common being large pins and tweezers. Vinyl weed cutters usually come with special weeding tools.

Some hobbyists enjoy weeding because it brings their designs to life. Others find it a tedious task to remove the subtleties from a complex design. Either way, it’s a necessary process you can’t avoid. Not all HTV’s are easy to weed, but they should be, so make sure you choose the right product.

5.5 Heat transfer process

First, select a heat press that can separate or “decorate” the garment on the lower platen to avoid sticking together when applying the image to the front and back of the garment.

Second, use Teflon protection on the lower platen to ease garment loading and reduce wear.

The third is to start production runs by shutting down the machine for one to two minutes to warm up the lower platen. The heating element dissipates heat during the first few cycles as it is absorbed by the cold lower platen.

Fourth, when using cold release transfer sheets, slowly release the heating element when you open the heat press. This action prevents the edges of the design from being lifted because the ink needs time to cure before the sheet separates.

Fifth, plug the heat press into a wall outlet that meets the proper voltage and milliamp requirements. Otherwise, proper heating will not be possible. Also, do not use extension cords, as electrical resistance loads will cause a fire hazard.

Sixth, pre-press the garment to remove excess moisture before applying the transfer sheet for better transfer adhesion.

Seventh, when heat pressing a dark garment, place PTFE or thin liner paper on the transfer sheet and garment to prevent dye transfer to the upper platen.

Eighth, when testing new transfer sheets, you can quarter them to prevent wasting multiple transfer sheets.

Ninth Periodically check the temperature of the platen using a digital surface pyrometer. This is the best equipment to use because its probe is in direct contact with the thermal element.

5.6 Lightweight heat transfer vinyl is better

Unless you are looking for a different effect, thin HTV is usually better. It’s also easier to cut and apply to surfaces by hand or machine. High-quality, thin HTV’s are placed flush with the fabric, resulting in a soft hand. Some companies emphasize the thinness of their HTV’s. They claim that it is “X% thinner than Rival Brand” or use phrases such as “so thin it feels like ink”.

5.7 Storage of Heat Transfer Film

Heat transfer film products should be lightly held and put, to put straight, vertical, and can not put horizontally; Can not be placed in the vicinity of the heat source, must be away from the heat source, generally at 25 ℃ under the preservation; Strictly prevent moisture, once the moisture, in use will be at high temperature plus source under the gas, and make hot ironing film chemical reaction. Therefore, the hot ironing film storage and to be used when should pay attention to moisture, moisture, pressure, to be placed in the ventilation cool and dry place.

Chapter 6. Types of Heat Transfer Films for Apparel

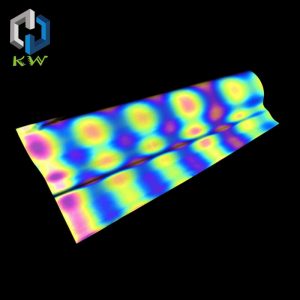

6.1 Reflective Heat Transfer Vinyl

Unique reflective properties, suitable for night work uniforms, to prevent life from accidental injury, suitable for all kinds of fabrics, generally by the labor uniforms factory clothing high-grade trademark selection. Industrial reflective materials mainly refer to five levels of various reflective films, such as A-class reflective film, high-strength reflective film, engineering-grade reflective film, advertising-grade reflective film, and license-plate reflective film. Mainly used for the production of a variety of reflective signs and markings, vehicle number plates, safety facilities, etc., in the daytime with its bright colors to play an obvious warning role, at night or in the case of insufficient light, its bright reflective effect can effectively enhance people’s ability to identify, see clearly the target, arouse alertness, so as to avoid accidents, reduce casualties, reduce economic losses, and become an indispensable safety guard of road traffic! The reflective heat transfer film has bright, obvious social benefits.

- Name: Reflective Vinyl For T Shirt

- Features: its bright reflective effect can effectively enhance the human recognition ability to see the target, arouse alarms

- Tear: Cold Peel

- Transfer temperature; 120-140 degrees

- Time: 5-10 seconds

- Pressure: 3-4 kg

Suitable for: cotton, blended and other kinds of clothing, chest LOGO hot label, and a variety of outdoor sportswear on the pattern of choice, environmental protection, water resistance, open personality charm!

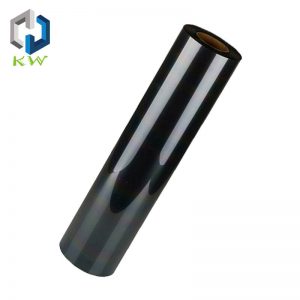

6.2 Rainbow Reflective Heat Transfer Vinyl

Rainbow Reflective HTV is a heat transfer flex that is made of fine glass beads. This is the upgrade version of normal Reflective flex which is better in washing durability and brightness. It is ultra-visible under a spotlight and shows off different colors when viewed at different angles, making it suitable for casual and activewear clothing. Also, it is very easy to cut and weed and is black when not reflective. Reveal powerful presence in the dark with Rainbow Reflective Heat Transfer Vinyl!

- Name: Rainbow reflective heat transfer vinyl

- Temperature: 150°C(302°F)

- Time: 10 seconds

- Pressure: Medium(bar 3.0)

- Peeling: Cold peel

- Made of High-intensity reflective beads

- Suitable for Leisure and activity clothing

- Very easy to weed

- Cut the finest of detail

- 14 colors available

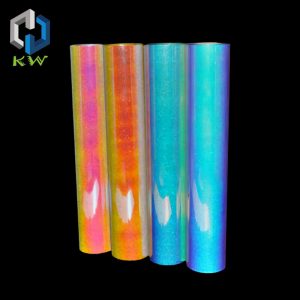

6.3 Holographic Reflective Heat Transfer Vinyl

Holographic Reflective HTV is made of environmentally friendly PET material: The first layer is PET protective layer, the second layer is the illusion reflective process and the third layer is polyester hot melt adhesive. No fading after heat press. It is high-temperature resistant. Hologram heat transfer vinyl is a dazzling effect with various colors. It is easy to use as a garment decoration. The special color effect differs hologram film from other heat transfer films. They are warmly welcomed by many designers.

- Name: Holographic reflective heat transfer vinyl

- Features: High reflective brightness, good effect, soft-touch, strong three-dimensional feel, easy to transfer, washable, environmentally friendly.

- Temperature: 150°C – 160°C

- Time: 10-12 seconds

- Peeling: Cold peel

- High-quality polyester (PET) film with high covering

- High temperature resistant

- Vivid color

- Good washing assistance: about 30 washing times, 30 minutes/time

- Easy to cut and weed

- No fading after heat press

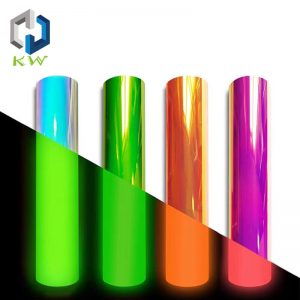

6.4 Luminous Heat Transfer Vinyl

The luminous heat transfer vinyl can be designed in various patterns and heat transferred to a T-shirt or other fabric, absorbing visible light for 10-15 minutes, and can continue to glow in the dark for 4-6Hour, keeping you safe and fashionable outdoors. Glow in dark heat transfer vinyl is made by photoluminescent powder, PU, and TPU material with a good feeling, high covering, and matte finish.

PET film of PU heat transfer vinyl is 100um thickness with high-temperature resistance and sticky backing. PU heat transfer vinyl is very easy to cut and peel. No fading and no deformation after high-temperature heat press.

- Name: Glow in dark heat transfer vinyl

- Features: It can be cut by cutting plotter and laser cutting machine; The minimum cutting line of images can be 1mm; Good washing resistance, over 20 washing times, 30-40 mins/time.

- Temperature: 302°F– 320°F

- Time: 10-15 seconds

- Peeling: Cold Peel, Peeling the clear pet film after the vinyl turns cold that just in 15-30 seconds later for the vinyl to cool down.

6.5 Glow In The Dark Holographic Heat Transfer Vinyl

The holographic luminous heat transfer film is covered with a layer of phosphorescent transparent film on the surface of the luminous heat transfer film so that it can be seen at different angles, different colors. And retain the luminous effect.

- Name: Glow in dark holographic heat transfer vinyl

- Features: The minimum cutting line of images can be 1mm; It can be cut by cutting plotter and laser cutting machine; Good washing resistance, over 20 washing times, 30-40 mins/time.

- Temperature: 150°C–160°C

- Time: 10-15 seconds

- Peeling: Cold Peel

6.6 Glitter Heat Transfer Vinyl

Glitter heat transfer vinyl has a 3Dfeel, irregular flash, and grinding effect.

It is suitable for transferring images onto textiles like cotton. blends of polyester/ cotton etc. This material comes with a self-adhesive carrier, which allows you to weed small vinyl and fine designs easily.

It can be cut by a vinyl cutter for printing name, number, logo, and design on T-shirts, sportswear, and other garments by a heat press machine. Its soft hand, strong adhesive, excellent durability, and washability are specially engineered for applying to T-shirts.

- Name: Glitter heat transfer vinyl

- Features: Durable, stretchable, washes fast and long last life of garments; High-quality PU material; It has a super clear, thick, and high-temperature resistant adhesive based layer which can hold cut-out images in place for easy transfer;

- Application: Used for any type of cloth material including 100% cotton, 100% polyester, and a mixture of both.

- Standard size: 0.5M * 25M;

- Temperature: 150°C–160°C

- Time: 10-15 seconds

- Peeling: Cool peeling;

6.7 Thermochromic Heat Transfer Vinyl

Thermochromic heat transfer vinyl is environmentally friendly and the color will change with temperature. It can be made with a cold or hot leather effect, or both cool peeling and hot peeling, depending on the customer.

Thermochromic HTV, based on PET release film. Can be used on cotton, polyester, etc.

It uses a special thermochromic powder and imported polyurethane / PU paste. It exhibits thermochromic discoloration at 28-31°C, but the second layer of color will appear at temperatures higher than 28°C. It can be washed 40-60 times for 30 minutes each time.

Chapter 7. Use The Equipment You Need For HTV

HTV’s manufacturer sells its products in bundles, which is reason enough to choose carefully. Also, make sure you have the right tools to make the job easy and comfortable. They include a computer with the right software for your design, and an ironing machine or heat press. You will also need a vinyl cutter or a cotton plotter. It sounds complicated, but it doesn’t take long to get the hang of it.

Tip: Some time can be wasted in learning and doing some testing on disposable garments.

7.1 Learn about heat press machine

All heat presses are not the same. Some manufacturers pay more attention to detail than others, so they pick reputable brands in the marketplace. The two standard heat element sizes are 15″ x 15″ and 16″ x 20″. If you’re not sure which size is best, choose the larger element; it’s often possible to heat press small patterns using a large size machine. For oversized garment decorations, heat press sizes can often be 20″ x 24″, 30″ x 40″, and larger as well.

7.1.1 Swinger or clamshell heat press machine

Swinger or clamshell: another decision is to choose a clamshell or oscillating mode heat press. As the name implies, clamshell designs have hinges on the back that open like a clam’s shell. These heat presses are popular in retail stores because they take up less counter space and are faster to produce because the heating element stays stationary. Sports lines and team uniform decorators often prefer swing-away heat press machines because the heat plates can be moved to allow the team member’s name and number to be listed on the uniform prior to heat pressing. Sublimation decorators also prefer this model because the heating element locks horizontally, reducing transfer slippage when heat transferring thick items such as wooden plaques and tiles.

7.1.2 Pneumatic Heat Press Machine

Pneumatic Heat Press: these heat presses are considered to be top of the line. Pneumatic heat presses provide quality garment-to-garment downward pressure, minimize operator fatigue, and provide precise repetition.

Chapter 8. Applying HTV With Household Iron

Are you going to start using an HTV but don’t have a heat press? Don’t worry, you can use a home iron to apply heat transfer vinyl sheet. Yes, it’s easier and faster with a heat press, but if done correctly, you can get a quality press with a home iron! Here are some considerations for using your home iron with your HTV.

1. Make sure that your work surface is set up so that it does not conduct heat easily. You will want to avoid any surfaces that will absorb heat from the iron and carry it away from your clothes. For this reason, we do not recommend that the worktop be an ironing board or granite worktop.

2. Some HTV‘s do work on different settings, but standard heat transfer vinyl should be used on ‘linen’ settings for domestic irons.

3. Heat transfer HTV’s are not ironed like shirts. You should leave the heated iron on the heat transfer vinyl for 25-30 seconds before moving to the next area. For this reason, we recommend that you cover your shirt with cover paper, kraft paper, or a tea towel. This will reduce the chance of burning shirts or other substrates.

4. Stress, stress, stress! One of the main reasons HTV when you use a home iron, the pressure is not always good enough and therefore the bonding is not always good. You will really want to put your weight on the iron. Pressing vinyl requires a lot more pressure than ironing clothes. Keep in mind that when you use a heat press, several pounds of pressure will be used. When applying vinyl, you do not want the glue to adhere only to the top layer of the garment, but to melt into the lower fibers of the garment.

5. Keep in mind that many irons cannot maintain a consistent temperature across the entire surface. Most home irons will get the hottest ironing in the center. For this reason, you will want to make it the ironing area for the vinyl coating.

6. If you find that some parts of the transfer do not stick when you peel off the liner, simply put the liner back in place and press again.

My iron doesn’t tell me what the temperature is – what should I do?

If you are using an iron, unlike a heat press, it adjusts and displays the temperature. Well, my iron doesn’t tell me what temp it’s heating to! Don’t worry, there are many ways to fix this problem. The first way is to perform a test. Use a small piece of fabric or an old t-shirt and see what happens when you iron the HTV at different heat settings. Using an iron, I found that using the hottest cotton setting and the lowest linen setting would work. This can mean higher cotton temperatures of about 300 degrees Fahrenheit. You can also use a high-temperature thermometer to test the temperature of the iron, but be careful not to burn yourself!

Chapter 9 What Items Can I Iron On With Heat Transfer Vinyl?

You can brand iron on anything that won’t melt! For starters, custom t-shirts, koozies, baby onesies, blankets, pillowcases, tote bags, dish towels, the possibilities are endless! HTV works best with cotton, polyester, or cotton/polyester blends. Other synthetic fabrics (such as acrylics) will not work properly as they will melt in the heat of the iron. For more advanced crafters, you can use HTV on mugs, baseball caps, soccer balls, or even wood! For more information on the surfaces applicable to HTV, see the test results below.

9.1 What surface does the HTV adhere to?

Have you ever thought about ironing t-shirt vinyl on an unconventional surface but wondered if it’s possible? Have you ever thought of a cool project involving a t-shirt vinyl and a surface that isn’t fabric and wondered if the vinyl would stick?

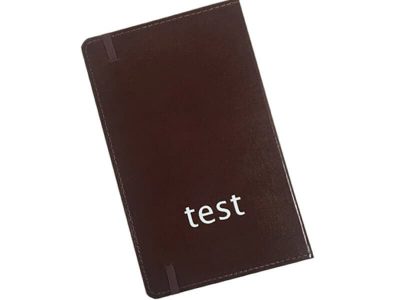

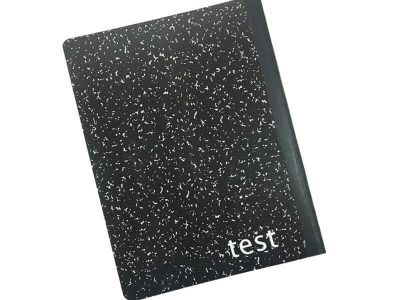

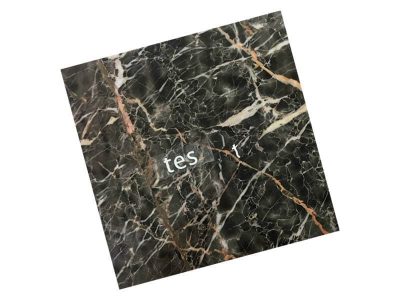

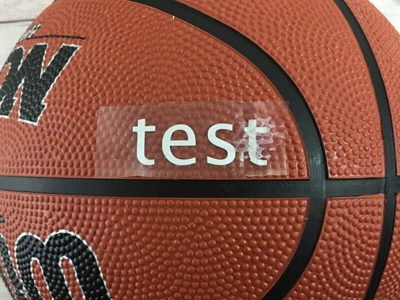

We are testing HTV on many different surfaces so you don’t have to! We try heat transfer vinyl on glass, acrylic, leather, canvas, cardstock, doormats, metal, felt, carpet, clay, cork, granite, marble, tile, linoleum, mirrors, and even basketballs! Stay tuned to see what works, what doesn’t, and our tips and tricks for ironing t-shirt vinyl on many different surfaces!

For this test, I only used some scrap we had left around the KWVINYL HTV product line and a piece of Teflon sheet for iron-on vinyl, to protect my iron and test subject. Since HTV involves HEAT, I made sure not to choose to test on any surfaces that might melt. If you do the same test at home, be safe! Don’t burn yourself!

I press my iron at 300-320 degrees Fahrenheit (or the cotton setting on the iron) on medium pressure for about 12 seconds. Once the hot press is done, cool for at least 20 seconds before removing the carrier plate, and the plastic gets hot! Look out!

HOW WE IRON: I ran this test on all normal heat settings and it worked great!

Result: the HTV adheres completely to the leather and does not feel like it comes off easily.

How we iron: If possible, a heat press would be the best way to iron on the canvas, as pressure is key on this surface. I use the normal heat setting to get the HTV to stick to the canvas, but make sure to press hard. An untreated canvas works best for heat transfer! If you’re looking for instructions on how to iron HTV on canvas fabric (i.e. not art canvas but canvas tote bags), then you’re in luck – HTV will adhere well to canvas fabric, but be sure to wash the canvas well.

Result: the HTV sticks well!

HOW WE IRONED: I ran this test on all normal heat settings and it worked great!

RESULTS: The heat transfer works well.

How we ironed: I used all the normal heat settings and it worked great!

RESULTS: This test works great! Since the cover of this notebook is actually cardstock, I suggest you try HTV as well!

How we ironed: For this project, I used a mini iron. Since the plastic would melt, I could only heat it for 4-5 seconds at a time.

RESULT: I was so afraid of the plastic melting that I was very careful, but the HTV did stick to the acrylic! This is very heavy acrylic. If you’re not sure about the durability of acrylic, run some tests. This experiment is a good illustration of why you need PTFE sheeting – if the acrylic melts, the melted plastic won’t destroy your heat press or iron! The test does work, but depending on what you are ironing on, we cannot guarantee that the HTV will always adhere to the acrylic.

HOW WE IRON: Since heat flows through the metal quickly, use a towel or oven mitt to secure the project metal if you plan to try this at home. We used a small iron for this project. This project required more time and pressure.

Result: the HTV did stick! And it seems to be very durable. For this test, I did all I could to strip the HTV from the metal, but it was hard to strip the HTV from the metal.

How we ironed: using the standard HTV setup and a lot of pressure.

Result: unfortunately, the project was almost a complete failure! I think it would work well on a corkboard that has less unevenness to it. The test cork was too rough, so applying a lot of pressure was very difficult.

How we iron: works great with standard HTV settings! HTV will bond the wood better if you treat the wood first. I use untreated wood and have had no problems!

Result: the HTV glued perfectly to the wood! If you are doing this project on very smooth wood, treat your surface with stain, paint, or polyacrylic first to give your HTV some grip.

How we iron: using standard HTV settings

Result: the HTV is stuck! For a more permanent solution, I recommend spraying a protective epoxy or polyacrylic topcoat to hold the HTV in place on the wood.

How we ironed: using the standard HTV setting. After a few minutes, I smelled a strange odor – probably the outer coating burning off – so I stopped ironing!

Result: Unfortunately, it didn’t work! The finish is too smooth for the wood to adhere to. Sanding it down first might help, but in any case, I wouldn’t recommend breathing in the smell of a chemical shine.

HOW WE IRONED: For this project, I used a mini iron. Again, the surface will transfer heat to your hands, so be sure to secure it with a towel or oven mitt if you are going to hold or grip the item. I used the normal heat setting to make the HTV stick to the glass.

Result: the release paper peels off easily and the HTV sticks well! A note on this item – HTV may be permanent, but if it is applied to a glass that passes through a dishwasher, or for items exposed to steam or heat, the HTV will fall off.

How we ironed: I wasn’t sure if the iron would melt the mirror, so I could only heat it for 5-7 seconds at a time. I used the mini iron because I didn’t want to risk melting the plastic handle with a larger iron.

RESULTS: I wouldn’t say the experiment was a success – the surface of the mirror was so smooth. It works better if you use a thicker HTV material (like glitter or flocking) and a shorter HTV design.

How we ironed: Based on the situation that unfolded earlier, I was more hesitant to apply a hot iron to a piece of carpet that could be very scorched. I started heating it for 2 seconds at a time, once I realized that the carpet wouldn’t burn (it did!), I heated it for another 8 seconds.

Result: Wow, I can’t believe the HTV is sticking to this shag carpet! My guess is that the carpet is polyester and that’s why it works. The iron and pressure really lower the pile of the carpet and flatten them out, making it lose its fluffiness, and honestly, it looks really weird! But the HTV does stick to the blanket!

How we ironed: I used the standard HTV setting and I wanted to mop it up for another second, the linoleum was too melted for my comfort.

Result: it worked great! The linoleum is just enough to absorb the HTV, so I know the HTV is stuck tightly there. I even tried using a weeding tool to strip the HTV, impossible to strip the vinyl. This would be a great way to recycle some old linoleum!

How we iron: using standard HTV settings

Result: the HTV did stick to the tiles! This tile has a bit of texture that I think adds the perfect amount of grip. This grip makes the HTV easier to adhere to. Since some tiles always seem to have a powdery feel to them, make sure to wipe any dust off the tiles before using HTV. HTV sticks well, but it feels as if HTV won’t stick permanently.

How we iron: using standard HTV settings

Result: Unfortunately, it didn’t work! The tiles we are using are very polished. I think this would be feasible without polishing the tiles as the HTV needs to be gripped again. As you can see, I can’t even peel off the carrier paper because the HTV isn’t sticking at all.

How We Iron: I wasn’t sure if the iron would melt the pad, so I could only heat the mini iron for 5-7 seconds at a time. This mat is made of polypropylene and has a melting point of 320 degrees Fahrenheit, so I made sure my iron wasn’t that hot.

Result: the vinyl on this doormat looks amazing! Like linoleum, I got the pad hot enough that the pad and the HTV became sticky enough to permanently bond together.

How we ironed: I used a mini iron and the standard HTV setting.

Result: it didn’t work! I thought the texture of the basketball was too uneven for the HTV to get a good grip.

Turns out the HTV is not only ironed with ease but it is also ironed with ease! What surfaces are you looking forward to trying?

Chapter 10. How To Use Heat Transfer Vinyl?

Now it’s time for the step-by-step tutorial!

Choose your design first. Today, I’m working on the session logo pocket t-shirt. When designing your project, be sure to measure the area you want to design and keep that size in mind.

It is wise to start heating the iron or heat press while designing and cutting. For the heat transfer vinyl, I am using, the iron must be between 300-315 degrees Fahrenheit. My iron only has the fabric setting, not the actual temperature. If your iron is anything like mine, choose a high cotton setting – low linen setting.

For this project, I’m using Silhouette Studio. open your design with whatever design software you want to use.

If you are using an image like mine, go ahead and trace it by clicking the butterfly button and selecting the area you want to trace. When the design looks OK, click Trace.

Immediately after tracking, mirror the design by finding the rotation icon and clicking one of the horizontal flip buttons.

Delete the original trace and now resize the design by dragging in or out the box on the design border. Silhouette Studio will tell you what size you want to design, so make sure it’s sized correctly! Two measurements, one cut will save you a lot of time and money!

Now you can start cutting! Depending on the type of HTV you are using and the machine used, the cut settings will vary. Be sure to test cut before cutting your design!

Make sure the vinyl is shiny on the mat facing down. Press “Load” on your computer. After checking the cut settings, press Cut!

The shear setting I used for this design is the Silhouette setting for automatic blade heat transfer vinyl smoothing preloading.

After the design is cut, press “unload” on the machine. Remove the vinyl from the mat.

Now it’s time to weed your design. Weeding is the process of using a pick or any other weeding tool to remove unwanted vinyl from your design. Please take your time and be sure to pull off any unwanted vinyl.

If your iron is all heated up, it’s time! Use an iron to preheat the fabric for 5-10 seconds. This step is crucial as it will evaporate any moisture that may be present in the fabric and damage your adhesive. Now, place the vinyl on your project so that the glowing side is facing up. If you have used text in your design, you will now know why you need to flip the design horizontally.

Thanks to the sticky substrate, your decal paper should be able to stick to the fabric. Make sure you use a PTFE sheet, rag, or parchment paper between the design and the iron. This will protect your irons and your project. Now you are ready to start heating. Again, remember to follow the instructions that are specific to your HTV type. I use Rainbow Reflective Heat Transfer Vinyl, so I will apply 300-315 degrees Fahrenheit heat for 10 seconds at medium pressure without a PTFE sheet, and 15 seconds with a PTFE sheet. If you are using another type of HTV, cut a small piece of heat transfer vinyl first to verify the adjustment of temperature and pressure.

After applying heat and pressure, resist the urge to tear off the carrier paper immediately! Wait about 10 seconds before doing so. It’s too hot at this point in any case! After 10 seconds, proceed with the operation and peel off the carrier plate. If used correctly, the carrier plate should peel off easily, leaving your design behind!

Now, if your vinyl looks as if it hasn’t fully adhered to the fabric, you can heat the design one more time before calling the project to completion. Cover your design again with the Teflon sheet and iron, or press for about 5 seconds more. Just to make sure everything is there!

Now you’re done! I hope I’ve answered all your questions here. As each project progresses you will get better and better and soon you will be an HTV professional!

Chapter 11. Thermal Transfer Film Ironing Defects Solution

Four steps to solve heat transfer film ironing defects.

- 1. Keep the machine clean: keep the important parts of the machine clean, not stained with oil and dust, keep the thermal transfer film clean, not stained with fingerprints and dust, keep the printing products clean, no dust, oil, keep the processor’s hands clean, no oil, no sweat.

- 2. Heat press temperature: heat press temperature on the thermal transfer product quality has an obvious impact, hot temperature is too high easy to damage the substrate, the hot temperature is too low may not be able to achieve normal transfer. The hot ironing temperature should be depending on the substrate, film, and thermal transfer machine these factors are to set, different materials have a different hot temperatures.

- 3. Heat press pressure: heat press pressure must be transferred to the most appropriate, otherwise too big and easy to hurt the rubber head and burned object, too small, and affect the effect of hot ironing. Transfer to the best hot ironing pressure should be after the pressure adjustment lock, lest mass production changes.

- 4. Ironing speed: ironing time (speed) should be determined according to the specific hot ironing material, in the case of ensuring the ironing effect, the faster the speed of production efficiency is higher, but some products due to some special conditions must be used slow ironing!

Chapter 12. Heat Transfer Vinyl T-Shirt Shedding Solution

Have you ever had an experience with heat transfer vinyl (HTV) peeling off a t-shirt or bubbles just after applying a t-shirt? This happens immediately after using a heating element (whether it is an iron or a heat press) and obviously, you are not happy about it. Well, you’ve come to the right place because I’m going to discuss what is causing this problem and what needs to be done to fix it.

How do you solve heat transfer vinyl stripping problems? The main cause of HTV flaking or bubbling can be due to incorrect stripping methods. There are always two methods that can be used for this process and they are hot and cold stripping.

There are other possible reasons why this happens. It is important for you to know all these things so that you can avoid this mistake, as it will waste your extra time and money.

If a mistake is made here, consider using vinyl letters to remove the solvent.

Other possible causes of stripping will be discussed later in this article. But first, let me discuss these two stripping methods and how they can lead to this problem.

12.1 Hot Peel Plastisol Heat Transfer Vinyl

This means that you can remove it from the object as it gets hot, which is the easiest way to do this. Please note that you don’t want to do this when it’s hot, as it can hurt.

If you let it cool completely, it should still work, it’s just that most hot peel heat transfer vinyl will take longer to remove once it has cooled completely.

Hot peel heat transfer vinyl has a liner, which is very sticky on the backside.

12.2 Cold peel plastisol heat transfer vinyl

This time, you have no choice but to wait until the object has cooled completely before peeling off the liner. If you don’t wait, the object will most likely warp, bubble, peel, or even stretch.

Cold peel-type vinyl will not have a sticky liner.

By now, you should have an understanding of how to deal with heat transfer vinyl peel issues.

These are other possible causes of your peeling problems.

I would like to add that if you want to remove the vinyl from your clothing, you can effectively use a solvent for vinyl removal letters. This will save you time, money, and you won’t have to throw away your t-shirt.

12.3 Not following the recipe

Formulations refer to the temperature, time, and pressure settings that are clearly defined in each HTV material.

12.3.1 Temp

In order for this HTV to work properly, the instructions for the recommended temperature must be strictly followed.

Therefore, I recommend that you use a heat press so that you can set the temperature and time correctly. You no longer have to worry about these settings being wrong.

12.3.2 Timing

Ironing or ironing for too short or too long can cause the HTV to peel off of your clothing.

Keep in mind that it takes enough time to press the HTV against the material for it to work properly.

If you don’t have enough time, it will not adhere properly. If it takes too long, it will likely burn the adhesive.

12.3.3 Pressure

Why you should use a heat press is another reason. It must be consistent throughout the application for it to work properly.

12.3.4 Things to consider when using an iron

This section is for those of you who still prefer to use an iron when using an HTV.

Of course, it is difficult to apply pressure to large designs if you are using an iron.

Experts say you should clearly see the weave of the fabric through the vinyl to ensure that adequate pressure is applied. This application of pressure requires strong upper body strength.

You should also consider the surface on which you place the T-shirt.

Do not use stones, granite, or other surfaces that will absorb the heat generated by iron. Also, do not use an ironing board or any other surface where you cannot apply constant, firm pressure.

If you would still prefer to use an iron instead, keep the following tips in mind.

- Use the cotton setting.

- Do not use steam.

- Do not place the hole in the bottom of the iron on top of the vinyl when applying.

- Apply as much pressure as possible when pressing the iron.

- Fifteen to twenty seconds should be sufficient time to do this.

A Cricut heat press is a good alternative to iron and will get the job done just fine.

Chapter 13. The Solution to the Glue Overflow of Heat Transfer Vinyl

Why do clothes sometimes have unsightly glue marks next to the pattern after heat transfer? How do you solve the overflow pressure of heat press vinyl film, especially on dark fabrics?

First of all, the overflow glue refers to the heat transfer film or hot ironing in the heat transfer printing, the bottom of the hot melt adhesive film melted to stay on the surface of the substrate, thus affecting the overall aesthetics of the pattern, dark fabrics are particularly obvious.

Will cause such reasons are mainly, the first use of heat transfer material does not apply to the current fabric, the second is the heat transfer temperature is too high caused by, and then the transfer pressure is too big, which leads to heat transfer hot melt adhesive melting penetration to the surface of the substrate.

So after analyzing the cause of the overflow, the solution is simple!

The first step is to find the type of fabric that the factory provides for transferable printing, be sure to heat press on the applicable fabric, and then be sure to follow the product transfer ironing parameters provided by the factory to adjust to the correct pressure. It is also important to follow the product transfer ironing parameters provided by the factory and adjust to the correct temperature.

Heat Transfer Vinyl Manufacturer Company In China

KWVINYL is a heat transfer vinyl film manufacturer that provides customers with heat transfer materials with superior print performance and specializes in the reflective and heat transfer industries. Superior heat transfer materials ensure the quality of the release, tensile strength, aging strength, and other details. KWVINYL is a professional manufacturer of heat transfer films and has its own coating chemistry laboratory. After more than 10 years of research and development, we are constantly upgrading our adhesive films and adjusting our coating formulations to meet market and customer needs and to obtain the most stable material ratios. At the same time, by adjusting the proportions of the different components in the film, we can change the opacity, release force, material size, ink absorption, and other properties according to the customer’s requirements. Once the recipe is finalized, the quality will be stable over time and will not vary from batch to batch. Therefore, you can use our heat transfer vinyl with confidence.

Our products are being sold all over the world, including the USA, UK, Canada, Holland, Germany, Spain, Argentina, Colombia, Korea, Japan, Italy, Dubai, UAE, Russia, France, Sweden, New Zealand, Australia, Vietnam, Bangladesh, India, and many more countries.

1. Unique advantages of thermal transfer film: There are various thermal transfer films in the market, KWVINYL always insists on two points: Firstly, all the materials of the color layer are of world-famous brand, never mixed with false; Secondly, the selection of process equipment, all follow the famous brand and leading technology to ensure the consistency of precision and quality.

2. Strong R & D and material integration advantage: The company has always put R & D in the first position of the company’s product development strategy, every year in R & D investment is the most important, whether it is the introduction of technical personnel, the purchase of testing equipment, the application of new materials and other aspects of the industry is second to none. Relative to other companies are most of the integration of products, acquisition of projects, do not have their own R & D system, product lineage is relatively messy, easy to lead users to fill in, can not one-stop shopping, diversified choice, resulting in confused users, frequent problems.

3. Heat transfer vinyl film products belong to the company’s core competitive products, from the project to market, always adhere to the principle of the user above, the company has a strong, perfect after-sales service system: the user’s needs is the direction of the United States Artspace efforts. One of the company’s principles is to liberate the user, add value to the user, and make products from the user’s perspective. In addition to the obvious application guide on the packaging box, there are product batches, use, storage precautions, and other markings, there is also a comprehensive product knowledge introduction on the company’s website.

4. Heat transfer film products have a unique adhesive layer: Compared to other products on the market, KWVINYL uses pure imported TPU hot melt media, which is coated by precision equipment. Compared to other products, we are praised for the range of applicability, weather resistance, adhesion, softness, environmental friendliness, and flexibility of our fabrics.

Heat Transfer Film You Need To Know These Things

In heat transfer film you need to know these knowledge points. The heat transfer film is a very deep study, especially just stepped into this industry, for some expertise is not very well understood.

What other supplies do I need to start making my own t-shirt?

You will need:

- Cutter

- An iron or hot press

- Weeding tools (you can usually pick and choose!)

- Scissors

- Cutting mat (optional!)

- Teflon sheets or parchment paper, or thin towels or rags

- Ironing boards or insulated surfaces

- Regardless of the fabric or material you use, such as a T-shirt

Why do you need to flip the design?

Before you cut the design, you need to flip/mirror it horizontally. This is because you are cutting it face down. If you are cutting it the right way (placing the vinyl face down on the mat and mirroring the design), peel off the design and see it applied to the surface with the correct reading. Hard to explain, but you are reversing the negative effects. Once you perform this operation the first time, it will always make sense! Just don’t ever forget to flip your design.

If your design does not contain text, you do not have to flip the text. Your choice!

Should I pre-wash the cloth?

If you’re not in a hurry to finish the project, I would definitely recommend pre-washing the fabric! If you’re ironing a t-shirt you just brought home from the store, imagine how dusty this fabric was at the factory. Any adhesive will always adhere better to a clean surface. For HTV to last, wash the garment with detergent and skip the fabric softener! If you finish your project but forget to wash your hands, don’t worry! Your HTV will still stay for a while.

Do I need to transfer the paper? Do I need a squeegee?

Good news- HTV’s binder pages are like transfer paper! So save the transfer paper as sticky vinyl. As for the squeegee, you don’t need HTV!

How long does it take for the heat transfer film to wash off and become stronger after transferring the vinyl?

Usually can be washed after transfer ironing, but after 24 hours is the most solid.

What is the production cycle of heat transfer film drink heat transfer logo?

The heat transfer film is a KWVINYL standing stock and can be shipped when ordered, heat transfer logo is a custom product and requires 3-4 days for proofing, 4-6 days for large shipments.

What are the three elements of heat transfer?

The three elements of transfer ironing are temperature (150-160°C), time (10-15s), and pressure (4.5kg/cm2).

Without an ironing machine, what do I need to be aware of when using an iron to iron patterns?

First of all, the heat transfer process is a good design, stick on a transparent PET material, through the heating device for thermal transfer to the bearer on the process, the iron has certain limitations, pressure and temperature is not enough, so in the use of iron stamping, it is necessary to ensure that the pattern of each side of the heat evenly, otherwise it is difficult to tear off the place is not heated, now commonly used are heat press machine to operate, more efficient.

Can I store the heat transfer film anywhere?

First of all, in the production of heat transfer film when the factory will pay special attention to the production space of the temperature and humidity, which also leads directly to the quality of the thermal transfer film, because when doing thermal transfer film, the use of glue, ink materials will be affected by the humidity color change, and ultimately cannot meet the accurate color requirements.

So in the production process will need to strictly control each link, the storage temperature is also recommended at 25 degrees above and below, available original packaging PP bag packed, the temperature is generally controlled between 55-65 degrees, unused products need to be neat and orderly erected, the indoor environment to be ventilated, air circulation is more conducive to preservation.

What are the storage conditions of heat transfer vinyl?

Cool, dry, and ventilated place, avoid high temperature and humidity.

Is it possible to do heat transfer on any fabric?

In addition to waterproof fabrics, shoes, clothing, and bags can be heat transferred.

Why are there dirty spots on the heat transfer film?

Many customers report particularly annoying problems whether they are transferring heat transfer film or heat transfer decals, such as dirty spots on the heat transfer sticker mark. Heat transfer film and heat press logo are good to use, but some of the details still need to be grasped. Let the 10-year old heat transfer film manufacturer share with you the best tips to avoid the appearance of dirty spots on the hot mark.

- First, check for debris on the heating plate.

- Check if there is any debris on the pattern itself to avoid dropping it during waste removal.

- Recommend placing a piece of silicone paper or breathable cotton cloth on the transfer surface to protect the pattern and fabric.

What do you need to pay attention to in the process of transferring heat transfer film?

Hot ironing of heat transfer film in the heat transfer industry is a common printing process, the principle of its work is very simple, through heating and pressure will be transferred to the graphics on the heat transfer film to the substrate, but in the specific practice, to improve the quality of the product and improve production efficiency, but also need to pay attention to the following points.

Keep it clean

- 1. Keep the machine table, guide rollers, buttons, and other parts clean and free from oil and other dirt;

- 2. Keep the film clean and free from oil, fingerprints, and dust;

- 3. Keep the rubber head clean and free from dirt and scorched lumps;

- 4. Keep the operator’s hands clean, no sweat or oil stains on the film or the hot product;

- 5. The operator’s hands should be kept clean, no sweat or oil stains on the film or the hot item;

- 6. Keep the hot item clean, with no dust or oil stains;

Three elements of heat transfer

Heat press time: 10-15s, according to the specific heat press to determine.

Heat press temperature: 150-160 ℃, heat press temperature according to heat press equipment, heat press film, heat press objects of different and different, can not blindly pursue heat press temperature is higher or (the lower the better), should be after the effect of heat press as a benchmark to determine the heat press temperature.

Heat press pressure: heat press pressure must be adjusted to appropriate, otherwise too big easy to hurt, and glue head and scalded object, too small and affect the heat press effect. After adjusting the heat press pressure to suitable heat press pressure should be adjusted to lock the pressure adjustment to avoid changes in mass production.

Does heat transfer vinyl last?

This actually depends on the type of heat transfer vinyl you are using. You should also avoid direct heat on the graphic. Typically, this t-shirt print style will last longer.

Will the iron come off when I wash the letter?

This will happen more in the dryer because the heat inside the machine can soften the fusible used in decorative applications. It is likely that these items were not cleaned properly before the design was added to the garment.

How do I remove heat transfer vinyl from a t-shirt?

Three separate methods can be effectively utilized to remove heat transfer vinyl from t-shirts. They are

- By using chemical solvents

- Application through direct heat and steam

- Through the use of iron

Can I use vinyl on a t-shirt?

No, it’s like putting a label on a garment, it simply doesn’t last. It doesn’t have any way to adhere or blend into the fabric used. Instead, consider using thermally conductive vinyl, as it will be more durable and last longer.

How big should my heat transfer sticker design be?

Regardless of what you are creating, be sure to always measure the design before you cut it. Below is a handy list of measurements for most t-shirt projects. Make sure to confirm these measurements using whatever project you’re actually creating!

- Adult T-shirt size: 11″ x 11

- Fitted adult t-shirt size: 9″ x 9

- Youth t-shirt size: 7″ x 7

- Toddler t-shirt size: 5″ x 5

- Baby onesie size 0-3 mo: 3″ x 3

- Baby onesie size 3-6 months: 4″ x 4

- Infant onesie size 6-9 months: 5″ x 5

- 9-12 month size baby onesie: 6″ x 6

- Sleeve length: 2″ x 11

- Pocket size: 4″ x 4

What if you don't want to iron right away?

If you want to wait for your ironing project, plan to give your ironing decal as a gift, or if you plan to travel with it, I recommend that you do not mow the grass until you are ready to iron. If you are giving your decal as a gift and want to weed it first, go ahead and roll it up using PTFE sheeting to protect the adhesive background. Then, you can tie it up with a bow and you’re good to go!

How well does the vinyl remain on the fabric after a few washes?

Depending on the type of heat transfer vinyl you use, iron-on vinyl will last longer than the t-shirt itself!

Always remember to turn your clothes inside out and wash them in cold water. If you accidentally forget to perform any of these actions, your item can be washed up to 6 times. If this happens and your vinyl starts to bubble and wrinkle, try ironing it again to make it smooth. Never throw any HTV in the dryer!

If you are using metallic vinyl (such as Foil), the shine will begin to fade after the first wash. If possible, try hand washing. A nice shiny finish is worth it!

I personally prefer to use iron. I feel like I have more control and it’s usually easier to plug in the iron and wait five minutes for it to get hot than it is to use a bulky, heavy-duty heat press. I also like to browse through my ironing projects while I’m ironing, which is almost impossible with a heat press. Having said all the traces of a heat press, I’d like to say that if you have access to a heat press, use it! It’s actually easier to calibrate every time with a heat press. A heat press is also a great tool because it heats evenly, which means that any edges of the decal paper pressed down won’t peel off. When we’re talking about wasting vinyl and t-shirts, it’s best to use a heat press to do it perfectly all at once.

What kind of craftsmanship does the three-dimensional pattern rely on?

In the summer, many men and women like to wear loose half-sleeved T-shirts, T-shirts above many people like to choose a three-dimensional pattern, like to be comfortable, pattern and with feeling! It has a super high return rate. So the question is, what kind of craftsmanship does the three-dimensional pattern rely on?

In fact, most of these three-dimensional patterns are heat transfer thick plate, heat transfer thick plate it specifically uses spot-toned ink printing, this printing method is also called screen printing, and flat hot stamping compared to the biggest feature is to have a clear hierarchy of three-dimensional sense, compared to some of the drop plastic trademark, copper die-casting and other processes can effectively reduce the use of cost, cost-effective is also very strong, in the visual belongs to the more high-grade type, can be said to be widely praised by customers.

The product pattern is clear and the color is bright! The lines are smooth and fluid, and the wash fastness is at European level 4 or higher, very much in line with the latest SGS environmental testing standards, and the product has also passed the Oeko-tex100 environmental test. The heat transfer temperature is 135-150 degrees and the heat transfer time is almost 10 seconds. The products are widely suitable for use in apparel, clothing, shoes and hats, toys, sports protectors, handbags, school bags, leather, and other handicraft industries.

KWVINYL’s thick board mylar can be described as medium elastic and very soft to the touch. It has excellent adhesion to all kinds of fabrics and has excellent washability and dry rubbing. The product also does not contain solvent derivatives and phthalates, very much in line with the United States, the European Union, Japan’s environmental requirements for children, all kinds of performance are better than the same price of the market products. It is also widely used in all kinds of textile printing and can be used in underwear and children’s wear. If you don’t understand anything, please email our customer service.

What do you know about heat transfer silicone rubber?

Heat transfer silicone rubber is one of the categories of heat transfer vinyl, its principle is to transfer the pattern to the hot object through heat transfer, it adopts the production process of glue and hot printing ink, the composition is environmentally friendly, soft touch, but also very resistant to stretch, washable, no glue edge on the surface, and not color migration, can keep the pattern color bright unchanged. As for the thickness, it can be processed according to the user’s demand, the thickness of the hot stamping material can be up to 1mm, which is suitable for synthetic fiber, cotton, knitted, and mixed fabrics.

- Name: Heat transfer silicone rubber

- Heat transfer temperature: 150℃-180℃

- Heat press time: 12-15s

- Heat transfer pressure: 4.5-5.5kg

- Tearing method: Remove the backing paper after it has cooled.

Speaking of which some customers may wonder, what is the difference between heat transfer silicone rubber and heat transfer thick plate? After all, it also has a three-dimensional effect, so the question arises, can heat transfer thick plate replace heat transfer silicone rubber?

The specific with the product requirements of quality to decide, like heat transfer thick plate is to use glue layer by layer drop brush up, wait until after molding and then with the pulling, twisting and other related actions can see very small cracks, and the heat transfer silicone rubber we are talking about today is liquid steel molding production method, will not appear heat transfer thick plate problem, feel also relatively soft a lot.

We have to say that KWVINYL silicone ink, no high-temperature curing, yellowing resistance, energy-saving, and very high humidity resistance, high-temperature resistance, UV resistance, strong adhesion, printing force, smooth and flat ink layer, and environmental non-toxic and harmless. It is also environmentally friendly and non-toxic, and fully complies with the EU environmental requirements for children, and most importantly, KWVINYL’s silicone inks outperform other similarly priced products on the market!

What are the characteristics of cycling clothing type heat transfers?

What are the characteristics of cycling clothing type heat transfers? That’s a question a lot of climbers are asking these days! The cycling jersey series refers to the clothing that cyclists wear from headbands, hats, pants and tops, gloves, etc., and so on. And precisely these clothing with branding on them are usually able to print logos and trademarks. The fabrics used in cycling clothing are highly stretchy, quick-drying, wicking, and moisturizing. So what kinds of these types of cycling clothing have been heated transfer technology?

First of all, the types of cycling clothes, we can divide them into short sleeves according to different styles. Jacket, long sleeve, vest, windproof jacket; pants can be divided into long pants, shorts, suspenders shorts, suspenders long pants, and so on.

Special note on the cycling trousers, usually with elastic lycra, this fabric can be close to the skin, the key is the crotch with functional padding, which can reduce the friction between cycling trousers and legs! It can effectively prevent inner thigh abrasion.

Then come to the function of heat transfer technology in cycling clothing, cycling clothing is normally through the production process is divided into two categories, heat transfer type cycling clothing and color matching cycling clothing. The characteristic of the thermal transfer class cycling clothes is that when printing the pattern, its color is bright can be printed on the cycling clothes, this point will not be like color-blocking cycling clothes because the style has too many sewing nodes and cloth piece.

Of course, because many cycling clothes are now using thermal transfer printing technology, so this industry will become more and more competitive!